_______________

The following write-up and photos were done by

Anthony Bulger. Steve Kan emailed them to

me. I added a few links to other

sections of my site for procedures on some of the steps Anthony has listed. Steve sent

me a Word file which I modified into HTML. The file had "Sequential" in the filename,

so these instructions probably apply to a sequential turbo setup (stock), so there may

be differences if you are going to install a Haltech on a non-sequential twin turbo or

a single. --Editor.

________________

From: Anthony Bulger, by way of Steve Kan Below are the steps that I took to install my Haltech E6K into my 93 RX-7. These are

in no way the "Complete" instructions for installing the E6K. I have provided information

that I believe is correct and accurate. However there may be mistakes in these notes

that can cause damage to your car. Any steps you take are your choice! None of the people

listed in this document are liable for you choosing to perform any of these steps. We are

only trying to provide help and information. Please remember to take time to perform any

and all repairs to your car in a safe and wise mannor.

Before you start your install take the time to read and familarize yourself with

the Haltech manual. The manual will describe how everything works on the unit and will

describe the install process for the basic unit. I suggest you borrow or buy a Workshop

Manual for your year model. Make yourself a clean workspace. Get some paper and a pencil

as well as a camera so that you can notate any steps you've made for future reference.

The install should take several hours and probably can be done in a day if you have

some experienced help. I took my time and spent 2 weeks on mine. I also performed some

other Mods at the same time which slowed my process somewhat. The install is really

not that bad however you will be somewhat overwhelmed at times. Trust me this is normal

even for the pros. If you are unsure of yourself PLEASE let a professional tuner

perform the install and Tunning process. This will quite possibly save you a popped motor.

This is a good time to change plug wires

or even do an Ignition Mod. With the Coil Rack removed you will see more of the ECU's

harnesses here to remove. I believe there is a grounding bolt as well as the connections

for the Water temp, Knock Sensor and, Oil Pressure sensor. I do not believe you have

to disconnect the oil pressure connections. If you are feeling daring you can remove

the Solenoid Hose rack. You will have to reroute these hoses for the Haltech anyway

and you can use this opportunity to clean this area as well as do a silicon hose

replacement. Warning! These hoses tend to be hard and brittle. The solenoids will

also be brittle. It is easy to salvage these if you take time and patience. One

trick I have learned over the years is to take a small Butane Torch and heat the hose

till it starts to smoke. Let it cool for a second or two then gentle twist and remove.

The hose may make a snapping noise when it breaks free. This is normal. Below is a

photo with the Manifold, Solenoid Rack and, Coil Rack removed.

Note: Cut the following wires below w/ approx 5-6" of length for possible future

solding. (in case we might need them afterall).

Now your harness should be ready for install. Just reinstall following the removal instructions.

Leave the motor torn down for the moment.

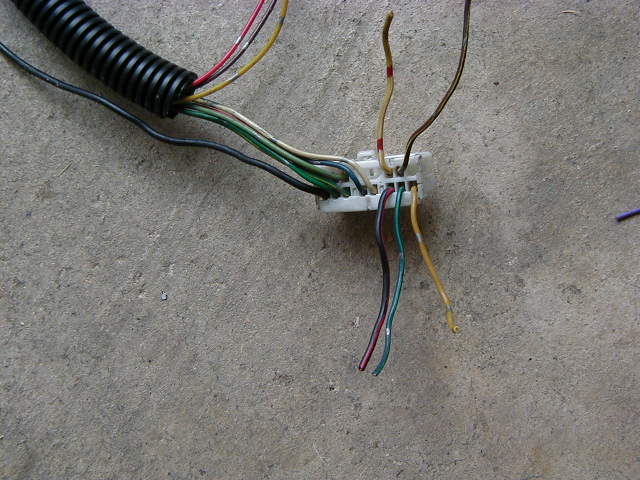

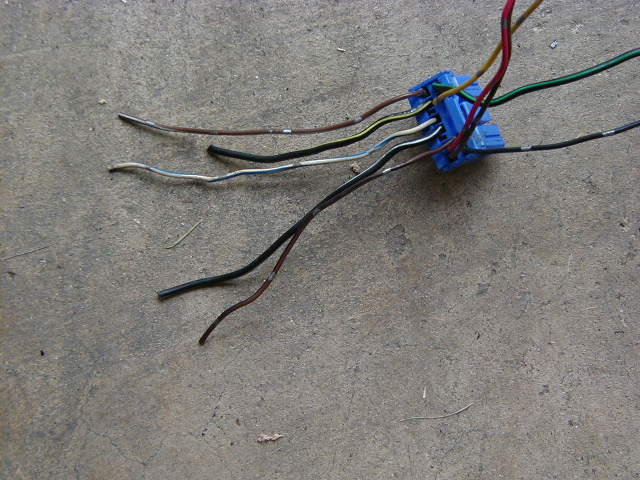

The following photo shows the Haltech terminated harness. I want to end this with some thank yous! I want to Thank Chris, Ari, and Solo from

Rotary performance. For whom whose help and tunning was cruical in the rebirth of my rex.

I want to thank Steve for helping in the install and pointing which wires to and not to

cut. I also want to thank Steve for helping me get the car running enough to drive her

to RP for final tuning. I need to put in a thanks to my neighbors for not complaining

about the Backfires and Fireballs I shot driving up and down the street when we were

tuning. That guy driving the mustang we passed is probably still tramatized from the

fireball I shot out the talepipe when passing him. Oh and let's not forget Steve

figiting with the laptop cord because the battery was dead, we stopped at Sonic to get

a coke and the fuel map got erased. I'm thankful he was well versed in the programing.

_________________

From: Jay Hanacek (Styk33@ricemobile.net) I looked at most of the EMS (Engine Management Systems) before purchasing

the Haltech E6K. I found the Haltech to be the best bang for the buck and it

had all the features that I needed for what I wanted the Ricemobile to be

capable of. I looked at Wolf, Electromotive, MoTeC, Apex and the PMC. All in

all, the MoTeC was by far the best, and the Apex Power-FC was the most

restrictive.

After getting the box in the mail I thought I had bought something that I

could not install. There were a lot of wires and a 150-page manual. After

reading threw the manual and looking at each part of the system that needed

to be install, I realized it is not all that bad. If you can install an

alarm with power window and remote start the Haltech is easy.

There are about 20 wire connections that need to be made. I left my main

engine wiring harness in and wired the E6K to the wires going into the stock

ECU harnesses. With those simple connections made it was on to pull some

wires threw into the engine compartment. There are three sets of wires that

needed to be in the engine bay. Three wires for the MAP sensor, two wires

for the coolant sensor, and two wires for the air temperature sensor.

Once the wires are in the engine bay you need to mount the MAP sensor. This

can be mounted were the stock Mazda one was since you don't need that one

anymore. As long as it is mounted above the top of the lower intake manifold

you are fine. The idea is to keep the fuel from being siphoned into the

sensor.

Then you need to tap and install the air temp sensor. You have a couple of

choices for this. You can mount it in the stock location like I did. Or

drill and tap a new hole for it and keep the stock sensor so you can go back

to stock easily.

The next sensor is the coolant sensor. I installed mine on the back of the

water pump, where the Mazda thermo sensor was. That sensor already had a

hole big enough for me to just stick my tap in and start tapping, instead of

trying to fit a drill in there with the water pump on. The hole that I used

is the lower of the two sensors and took about 30 minutes to tap due to its

location.

The two major connections that need to be made that don't connect to the ECU

harnesses are for the power and ground. Run the ground to the battery or a

good chassis location. The positive wire should go straight to the battery.

There are many options to connect the fuel pump. I connected one of

Haltech's fuel pump wires to constant power and the other one to the

white/red wire under the master cylinder. That wire goes straight to the

fuel pump without any relays interfering. This also allows you to disconnect

the factory fuel pump resistor (looks like a little heat sink). The Haltech

has a relay that controls when the fuel pump gets power, so my fuel pump is

not running all the time so connecting to the batter is fine.

After all that work, I loaded up my base map and checked all the sensors and

started the car. It started up after a few seconds, due to my tiny battery.

After playing with the maps and stuff for a few days straight, I have made

my car run nice and smooth for the most part. A lot better than the M2 ECU I

had in there. Not that, that ECU was bad, just different.

And for all the folks that say there gauges don't work or the A/C, cruise

control, power steering, sequential turbos, turbo timers and whatever other

BS you can think of. All my gauges worked fine with only one wire I had to

hook up additional to the E6K. My A/C worked (for about two minutes, then I

tore it out). My cruise control works and everything else. I used the stock

TPS, stock coils, and igniter. I also used the internal reluctors on the

E6K. The stock MAP, coolant and air temps sensors can also be used. Keep in

mind that the stock MAP is only good up to 2 bar (~15psi), so if you want to

run more boost you need the 3 bar (~30psi) sensor from Haltech.

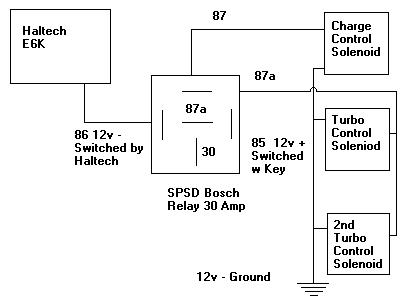

The E6K has some additional outputs to control extra goodies. You can

control when the radiator fans turn on and off. There are other features

like, sequential turbo control, IC fan, shift light, turbo timer, NOS

controls, boost control, and for those of you crazy guys out there anti-lag.

It also has a flat shift and a 2-step ignition available for you drag

racers.

I have also got rid of my Apex AVC-R and am running the Haltech

solenoid/boost control. The Haltech boost controller works the same as the

AVC-R just not all the fancy lights that I didn't like. The thing that the

Haltech controller lacks is the fuzzy logic and a gear adjustment for boost.

Since your load is increased in higher gears you are more likely to build

more boost. This means I hit the boost cut (not fuel or ignition cut) on the

Haltech boost controller in 5th gear. I plan to go back to the AVC-R in the

future, but until then, the Haltech controller is good. If you never went to

a stand-alone boost controller before upgrading to the Haltech you can

utilize this feature in the Haltech and save some money.

Tuning Hints and Stuff

A little advice on some situations I have had with my car. If you car takes

a long time to start compared to the factory ECU during cold winters you can

enrich you coolant correction map threw all levels below 60F. This helped my

car immensely for starting. Since your car runs no cooler than 150F when

actual driving this will not effect the car except under starting conditions

and part of the warm-up. I also added fuel to the 0RPM range since the

Haltech pulls from that map during starting.

Remember to keep the gap between the primary and secondary fuel injectors

the same level all the way threw the RPM range. Otherwise you will have a

stumble when you get on boost. The change over on my maps is setup to happen

at around 1psi. The way to tell were it is happening is by looking at the

bars, the primary injectors are shaded and when the primary and secondary

injectors are on, they are just blank bars.

I have leaned out a lot of the extreme vacuum areas (>22psi) since they are

not normally scene during cruising and only during shifting. Since doing

this I don't have any unburned fuel igniting in the exhaust causing

fireballs. Flamage is an attention getter at the drag strip, but that is not

what I am going for. Be careful not to lean these sections out too much. If

you do, then under light cruising throttle you will have surging due to the

lack of fuel.

I am planning on putting up some different maps of different engine setups

in the near future. Stock turbos stock fuel, along with upgraded fuel and

T-60, T-66 and the T-78 turbo. Of course these maps will only be a baseline

for someone's car since all setups are different.

If you have any questions, please email me or ICQ me. If I don't have the

answer there are a couple hundred of us Haltech owners on Yahoo Groups at

'Haltech-Support' that might be able to help.

Here is an older version of the previous post, in case there is anything here that is

not included with Jay's original post. --Editor.

From: Jay (styk33@yahoo.com) I bought and installed my E6k a couple weeks ago. I have been getting email and phone

calls about it in the past couple weeks. So I figured I would post something for those of

you that to shy to ask questions

After getting the box in the mail I thought I had bought something that I could not install.

There were a lot of wires and a 150 page manual. After reading threw the manual and

looking at each part of the system that needed to be install, I realized it is not all that

bad.

There are about 20 wire connections that need to be made. I left my main engine wiring

harness in and wired the E6K to the wires going into the stock ECU harnesses. With those

simple connections made it was on to pull some wires through into the engine compartment.

There are three sets of wires that needed to be in the engine bay. Three wires for the

MAP sensor, two wires for the coolant sensor, and two wires for the air tempature

sensor. I also connected my fuel pump wire in the engine compartment instead of using

the stock relays like other. So that adds another wire that need to be pulled through the

firewall.

Once the wires are in the engine bay you need to mount the MAP sensor. This can be

mounted were the stock Mazda one was since you don't need that one anymore.

Then you need to tap and install the air temp sensor. There are two places that you can

do this. One is on the upper intake manifold and replace the stock one. This is where I

put mine. You could also do what someone else did and leave your intake manifold on and

tap your intake elbow. This will put the temp sensor before the TB instead of after. It

also puts it off to the side of the motor instead of above it. Not the best spot, but would

work for a temporary weekend install if you want to leave your UIM on.

The next sensor is the coolant sensor. I installed mine on the back of the water pump,

where the Mazda thermo sensor was. That sensor already had a hole big enough for me

to just stick my tap in and start tapping, instead of trying to fit a drill in there with the

waterpump on.

The two major connections that need to be made that don't connect to the ECU

harnesses are for the power and ground. Run the ground to the battery or a good chassis

location. The positivie wire should go straight to the battery.

My fuel pump connection was the confusing to some people, but simple in my mind and

others that helped me. This was the one problem that I had when my car wouldn't start. I

tried to use the stock relays and that didn't work. So I connected one of haltech's fuel

pump wires to constant power and the other one to the white/red wire under the master

cylinder. That wire goes straight to the fuel pump without any relays interferring. The

Haltech has a relay that controls when the fuel pump gets power, so my fuel pump is not

running all the time.

After all that work, I loaded up my base map and checked all the sensors and started the

car. It started up after a few seconds, due to my tiny battery. After playing with the

maps and stuff for a few days straight, I have made my car run nice and smooth for the

most part. A lot better than the M2 ECU I had in there. Not that, that ECU was bad, just

different.

And for all the folks that say there gauges don't work or the A/C, cruise control, power

steering, sequential turbos, turbo timers and whatever other BS you can think of. All my

guages worked fine with only one wire I had to hook up additional to the E6K. My A/C

worked (for about two minutes, then I tore it out). My cruise control works and

everything else. I used the stock TPS, stock coils, and ignitor. I also used the internal

reluctors on the E6K.

The E6K has some additional outputs to control extra goodies. You can control when the

fans turn on and off. There are other features like, sequential turbo control, IC fan, shift

light, turbo timer, NOS controls, boost control, and for those of you crazy guys out there

(Eric) anti-lag. It also has a flat shift and a 2 step ignition availible, but I have not got

these to work yet.

All in all I am very happy with my purchase. I plan on running the Haltech boost control

next month and I will report back on what that is like compared to my AVC-R.

If I missed something or anyone has some questions I will try to help. I know there are a

couple of you out there that have E6Ks and might have some other input.

________________

From: Mike Ack! Let me quote you to get it right:

Heh, Jay is refering to me. I stuck that damn sensor right in my Greddy elbow. I believe it

works great. I have seen no draw back. But, as Jay says its not inside. But, I use this

sensor to determine what my air intake is from the IC. The one inside will do the same,

but, it will prolly rise a degree or 2 due to the extra metal.

Anyhow, thanks Jay! hahaha.

Haltech Installation

Date: September 18, 2000

Tools and Supplies:

Procedure:

Date: April 4, 2001

RX-7

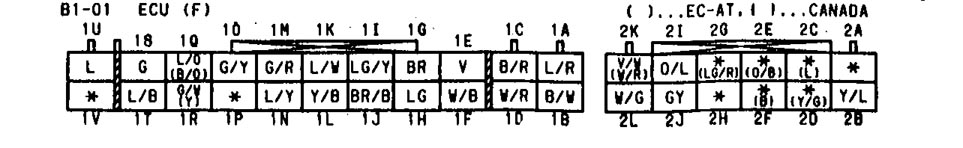

Harness to E6K Harness

E6K

Conn

Description

4E

Yellow

Yellow

J16-B

Crank NE +(Trigger)

4H

Red

Red

J16-C

Crank NE -(Input A)

4H

Red

Blue

J16-D

Crank G -(Input B)

4G

White

Green

J16-E

Crank G +(Home)

4W

Lt. Green/Red

Lt. Blue

J13

Injector 1 (Primary)

4Y

Lt. Green/Black

Blue/Red

J13

Injector 2 (Primary)

4X

Lt. Green/White

Green/Red

J13

Injector 3 (Secondary)

4Z

Lt. Green

Pink

J13

Injector 4 (Secondary)

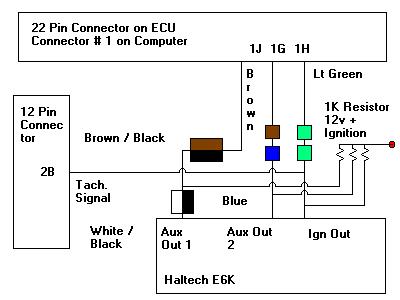

1G

Brown

Blue

J7

Front Igniter (Digital Out 2)

1J

Brown/Black

White/Black

J7

Rear Igniter (Digital Out 1)

1H

Lt. Green

Lt. Green

J7

Leading Igniter (Igniter Out)

1T to 1K

Orange

Flying

Fuel Pump Relay (Connection 1)

Connect to

Chassis (-)

Orange

Flying

Fuel Pump Relay (Connection 2)

Connect to

Battery (+)

Red

Flying

Main Power

Connect to

Chassis (-)

Black

Flying

Ground

1B

Black/White

Gray

Flying

Ignition Power

3D

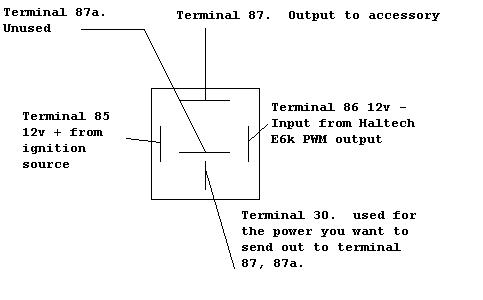

White/Blue

Violet/White

J18

PWM1 (Radiator Fans)

4Q

Lt.Blue/Green

Pink/Black

J18

PWM2 (BAC)

1L

Brown/Black

Blue/Green

J18

PWM3 (A/C)

2J

Gray

Green/White

J18

PWM4 (Air Pump)

3C

Black

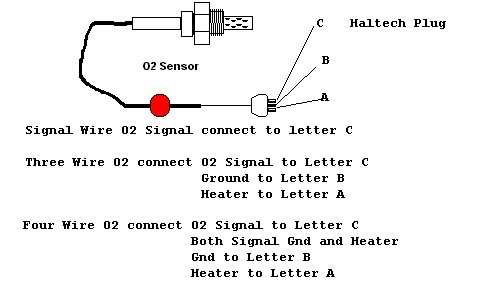

Gray

J6

O2 Sensor

1M

Green/Red

Gray/Yellow

J17

Road Speed

4D

Brown/Black

Black

J10-A

TPS (-5V)

3G

Black/Green

White

J10-B

TPS (Signal)

3I

Brown/White

Orange

J10-C

TPS (+5V)

3L

Green

Gray

J11-B

Air Temp Sensor

3E

Green/White

Violet

J12-B

Coolant Temp Sensor

Stock ECU to

Stock ECU

1H

Lt.Green

2B

Yellow/Blue

Tachometer Signal

1T

Blue/Black

1K

Blue/White

Connect these to Fuel Pump Relay

Date: August 12, 2000 12:11 AM

Date: August 17, 2000 01:46 AM

>You could also do what someone else did and leave your intake manifold on and tap your

>intake elbow. This will put the temp sensor before the TB instead of after. It also puts it

>off to the side of the motor instead of above it. Not the best spot, but would work for a

>temporary weekend install if you want to leave your UIM on.