By Shiv Pathak

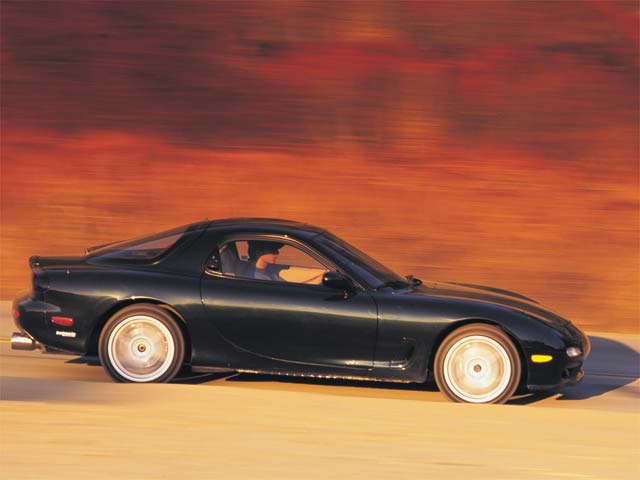

In the first installment of our Project RX-7 series, we covered the performance-related

strengths and weaknesses of a bone stock RX-7. In this installation, we will focus on

preparation and taking the precautionary measures necessary to make Project RX-7 a

streetable and reliable road racer. To address these requirements and plan our series of

upgrades, we took our Project RX-7 to Mostly Mazda in Concord, Calif. Visiting Mostly

Mazda is quite a visual experience. Arranged neatly in their parking lot are more than

a dozen shiny RX-7s. Primarily of third generation ilk and few of race-prepped variety,

the colorful fleet of rotary powered sports cars appropriately describes Mostly Mazda's

professional expertise.

In the first installment of our Project RX-7 series, we covered the performance-related

strengths and weaknesses of a bone stock RX-7. In this installation, we will focus on

preparation and taking the precautionary measures necessary to make Project RX-7 a

streetable and reliable road racer. To address these requirements and plan our series of

upgrades, we took our Project RX-7 to Mostly Mazda in Concord, Calif. Visiting Mostly

Mazda is quite a visual experience. Arranged neatly in their parking lot are more than

a dozen shiny RX-7s. Primarily of third generation ilk and few of race-prepped variety,

the colorful fleet of rotary powered sports cars appropriately describes Mostly Mazda's

professional expertise.

Modification Caveats

According to Brian Richards, the owner of Mostly Mazda, the third generation RX-7 can be

a very reliable automobile. However, as an ultra-sophisticated, lightly disguised,

rotary-powered race car, it demands special care. Before modifying the RX-7, one must

become aware of its unique subtleties. One characteristic of the RX-7's unusual powerplant

is its absolute intolerance to detonation. Unlike most conventional reciprocating engines

which are able to withstand the abuse of knock, rotaries can fail (or at least become

seriously compromised) with just a single, serious ping. This is one reason that rotaries

are designed to run exceptionally rich air/fuel mixtures compared to their piston-laden

counterparts. The RX-7, like most OEM turbocharged cars, is equipped with an electronic

knock sensor that keeps a constant vigil for the tell tale signs that usually lead to

knock. Although Mazda has taken many precautions to keep the 13B running reliably and

trouble-free, the powerplant is anything but foolproof-- especially in the hands of an

inexperienced tuners.

"The FD (Mazda's designation for third generation RX-7) comes equipped with a MAP (Manifold Absolute Pressure) sensor, not a typical MAF (mass air flow) sensor" states Brian, "This mean that the stock ECU does not readily compensate for increased flow caused by exhaust back-pressure reductions or a intake upgrades. Reading only manifold pressure, the stock ECU relies on fixed maps that no longer deliver the required fuel for the increase in volumetric efficiency. Under this situation, a momentary lean-run condition can easily lead to detonation and apex seal damage."

Another potentially disastrous complication that plagues many over-enthusiastic shade-tree mechanics has to do with the FD's sophisticated sequential twin turbocharger system (see technical side-bar). Tuned carefully by the bright engineers at Mazda, the twin-turbo system offers nearly seamless power output from idle to redline. Controlled by numerous solenoids, countless vacuum lines and various mechanical actuators, the turbo control system is designed to deliver a consistently safe boost pattern and optimal driveability. However, problems immediately arise when cats get gutted, intercoolers upgraded, and free-flow exhausts installed. Since the boost control system operation relies on manifold pressure and exhaust back-pressure, a dramatic change one or the other can result in a severe over-boost situation. Brian comments, "This problem becomes most obvious during the transitions to the secondary turbo when boost pressure can momentarily spike several PSI. This short-term spike can lead to detonation and, almost always, blown motors." Similarly, a denser, cooler intake charge, from the use of more efficient intercooler units, can contribute to lean-run conditions if not met with appropriate EFI system modifications. For this reason, Brian suggest that even a relatively simple bolt-on upgrade is best accompanied with appropriate boost, timing and fuel re-mapping.

So what about all those RX-7s that only sport the "latest and greatest" bolt-on upgrades with no attention to ECU modifications? According to Brian, although these cars seem to be perfectly functional under short to medium-term use, they are often 'ticking time bombs', waiting for the right set of circumstances to self-destruct." Brian recalls several mildly modified RX-7 that have been towed to his shop suffering from blown apex seals. "Most people just don't realize how necessary it is to have a margin of safety associated with these engines," Brian remarks, "One owner who lived in northern California had an RX-7 with a free flow exhaust, intake and intercooler upgrade. With the stock fuel and boost management system, it ran a little on the lean side. For several months he drove the car to work every morning with no obvious problems. Finally, on an unusually cold, winter morning, the engined leaned-out and pinged once under boost. When he came to stop, the idle was lumpy and his motor was toast."

As an experienced road racer, Brian knows the importance of long term durability. A minor engine problem can mean the difference between first and last place. Mostly Mazda's goals is to improve reliability while still offering competition-like levels of performance. Although many may view his upgrade precautions as excessive, Mostly Mazda's performance record on the race circuit and on the road speak for itself. Starting in Part III of this series we will begin our power-enhancing upgrades, carefully following Mostly Mazda's upgrade stages.

Thermally Challenged?

It doesn't take much time for a new RX-7 owner to realize that the RX-7 twin turbocharged rotary engine generates enough under-hood heat to warm a small Icelandic village. In fact, after a long drive, only select Buddhist monks capable of carrying a red hot cauldron by their forearms are able to lift the front hood and prop up the support without yelping in pain. How did Mazda ever expect to sell this car to an owner whose idea of self-sacrifice is a self-serve gas station? While not blistering enough to melt the clear coat off the hood and fenders, the under-hood temperatures are hot enough to prematurely age and harden the rubber hoses and lines in the engine bay. With the help of Mostly Mazda, this is another area we will focus upon in our series.

Another "soft spot" in the RX-7's armor is its cooling system. As we have seen in Part I of this series, our on-track testing at Thunderhill raceway made the car run uncomfortably hot under the collar. To our dismay, a quick inspection of the engine bay reveals a relatively small-capacity radiator. Egad! Why such a puny radiator in an automobile that Mazda advertisers used to call a "race car for the streets?" Just in case its meager dimensions were not bad enough, unlike most radiators which mount vertically to receiving maximum air flow, the FD's unit is mounted with its bottom slanted backwards at a nearly forty-five degree angle! Although equipped with appropriate ducting to channel its share of air, much of the radiator is obscured by a large AC condenser unit. While we think much of the RX-7s overheating problem could be ameliorated by the removal of the AC system, we feel that doing so would destroy much of the RX-7 everyday utility during our highway cruises to and from the racetrack. In other words, why should we profusely perspire and dread trips to inland California just because Mazda didn't want to spend the extra bucks to use a more efficient radiator?

A bit of research suggested that we weren't the only ones who have complained of overheating third gens. In fact, most of Brian's customers who engage seriously in track events experience cooling problems. We will attempt to eliminate Project RX-7's overheating tendencies with a little help from Mazda Competition's parts bin. We will be installing their larger capacity race radiator in the Part III of our series.

Getting Started

The first step in any project is proper preparation. These precautions are perhaps the

best insurance against mishaps during your upgrade process. These maintenance items should

be regarded as mandatory, not optional.

As with any new (or used) car, the first stage in maintenance involves changing all vital fluids. This is especially critical for our purposes since the car will be required to perform under full loads for extended periods of time. Until our racing radiator is installed, we make the best of our stock cooling system by flushing and replacing the coolant mixture. Mostly Mazda recommends using a 70/30 mixture of distilled water and coolant. We also added the recommended dosage of Redline Water Wetter to further improve heat dissipation. Using only water is not recommended and is potentially damaging to the water pump mechanicals due to its insufficient lubrication and anti-corrosive properties.

Dino or Synthetic motor oils? That's the big question. While Mazda Corp. has officially forbid the use of synthetic motor oils in their rotary engines, Mostly Mazda strongly recommends the use of Redline synthetics products, in the motor, differential and in the transmission. The unofficial "inside story" behind Mazda's statement is quite interesting. Apparently, in the early 1980s, Mazda's racing team had lubrication problems using a certain brand name synthetic motor oil. Instead of disclosing the particular oil brand and potentially getting faced with a lawsuit, Mazda made an unfair general statement, suggesting that all synthetic oils were incompatible with their rotary engines. Redline motor oils have been successfully used in rotary race motors for nearly two decades. Their motor oils offer improved film strength over other motor oils, synthetic or non-synthetic. Synthetics also extend the life of the turbochargers by resisting bearing "coking" typically associated with traditional oils. We used Redline 10W/40 high performance motor oil for Project RX-7. At over six dollars a quart, it is hardly inexpensive. However, a good motor oil is the best insurance against premature engine wear.

Evidence supports that synthetic oils may not burn as cleanly as dino oils. According to Mostly Mazda, this residue may potentially cause premature clogging of the catalytic converter over a very long period of time. This relatively minor problem is easily remedied by catalytic converter replacement. Such maintenance is far less expensive and time consuming than replacing engine or turbo damaged by insufficient lubrication.

Fuel related problems can also bring a quick death to the RX-7. Brian has seen many blown rotary engines caused by something so trivial as a dirty fuel filter. The stock fuel filter, while sufficient to support a 140 horsepower Miata for 60,000 miles, needs to be replaced more frequently in the turbocharged RX-7. Brian strongly recommends the replacement of the fuel filter every 15,000 miles. As seen in the photographs, the fuel filter is located well above the rear differential, making it very difficult to find, let along replace. In fact, it is often neglected by owners and sometimes avoided in regular dealer maintenance. Again, we viewed replacing the fuel filter as cheap insurance against fuel related problems.

The next stage of preparation is much more time consuming but equally important for longevity and performance. Under the manifold, there exists a proverbial "rat's nest" of seventy-six vacuum lines controlling, among other functions, the sequential operation of the turbochargers. It is not uncommon for these lines to harden over time from under-hood head and eventually crack open or loosen completely. It only takes one loose line to "throw a wrench" in the entire turbo control system. The most common symptom of such a malfunction is erratic turbo performance. Often the secondary turbo will fail to produce normal boost pressures. A more catastrophic failure occurs when the boost/vacuum signal to the fuel pressure regulator pops off. When this happens, fuel pressure doesn't rise when driven under boost. As a result, you guessed it, motor failure. All these problems are avoidable with a few hours a labor and a big bag of tie wraps. This modification, however, is best left to the professionals as it requires disassembly of the intake manifold and associated components.

As most third generation RX-7 owners will attest to, there is another performance quirk associated with their cars. Under cold operations, most owners complain of a 3000 rpm hesitation. Varying in intensity from car to car, it could range from a mild "hiccup" to a serious buck until the car reaches normal operating temperatures. To ease this electrical system related oddity, Mostly Mazda installed a hefty grounding strip from the engine block to the chassis.

Taking all these quirks into consideration, it is easy to understand why the third generation RX-7s earned a reputation for poor reliability and quirky performance. Improperly trained dealership mechanics were given the unfair responsibility of working on a car far more sophisticated than the previous Mazda vehicle. This often led to more problems and hefty repair orders. It has taken a while for the RX-7 to become a viable daily driver. During the early years of its production, when knowledge was a scarce commodity, most third gens spent more time at the dealership than on the road. It has been semi-seriously suggested that people pass a test before being allowed to own one of these cars.

Another modification is the installation of necessary instrumentation. The two most critical, but unchecked, areas in the RX-7 are boost pressure and fuel delivery. A problem with either can lead to serious engine damage. Mostly Mazda installed a boost and fuel pressure gauge from Auto Meter's attractive "Ultra-Lite" line-up. These two inch gauges were nicely fitted in Auto Meter's RX-7-specific dual A-pillar gauge holder. Both gauges were easy to install, as was holder. A boost signal was sourced from an unused nipple on the intake manifold (closest to the ABS electronics). Requiring the installation of a sender in the fuel line, the electric fuel pressure gauge was a little more involved. Mostly Mazda installed the small sender in the insulated fuel line (near the engine oil dipstick) with a simple "T" fitting. The wiring from the sender was passed through the firewall to a small electronic control module which we stashed in the driver's side foot-well, behind the plastic paneling near the fuse box. The wires from the control module were routed to the gauge, inconspicuously through the base of the A-pillar mount. Compared to mechanical fuel pressure gauges, the electric unit is far superior. Without the complication of passing a steel braided cable, filled with coolant, through the firewall, the installation is simple and maintenance-free.

As with all turbocharged engines, a proper "cool down" period is necessary after spirited driving to avoid coking the turbo bearings. Although synthetic oils help, a minute or so of prolonged idling is always advised. On the race track, several minutes of idling is believed to be necessary, allowing the different engine components to recover from their various thermal expansions. This can prolong the life of the seals between the rotary housings and help prevent premature cracking of the turbo housings and exhaust manifold.

Tired of siting in a hot car on a hot day, we installed a Blitz "Skeleton" turbo timer. Following the functionality-theme of our project, this helpful device sports a see-through plastic housing and provides hours of entertainment for your technically astute electrical engineering friends. Installation was a five minute job with Blitz's custom wiring harness. Once working, the turbo timer keeps the engine running after you turn off the ignition, allowing a user-programmable "cool down" period ranging from ten seconds to ten minutes. Once again, cheap insurance against an expensive turbo or engine rebuild.

What The Future Holds...

For the first time in its five year life, Project RX-7 is running flawlessly (despite its

on-track cooling problems.) As it is, this sports car could keep us endlessly entertained.

For most people, there is little need to modify our RX-7 for enhanced performance. In the

present form, it is far beyond the performance capabilities of anything this side of the

$100,000 Porsche 911 Turbo. With the help and guidance of the guys at Mostly Mazda and a

few top-notch aftermarket retailers, we will attempt to improve every aspect of the RX-7s

already stellar prowess while minimizing daily driving compromises. We are planning quite

a comprehensive "build up", ranging from a host of Mostly Mazda's power-enhancing upgrades

to a ne plus ultra brake system from Cooltech. Stay tuned for the fun stuff!

Sources

Mostly Mazda

2111 Freemont Street

Concord, CA 94520

(925) 686-9047

Greddy Performance Products

9 Vanderbilt

Irvine, Ca 92618

(949) 588-8300 (Tel)

(949) 588-6318 (Fax)

www.greddy.com

Blitz U.S.A.

4879 E. La Palma Suite 206

Anaheim, Ca 92807

(714) 777-9766

Auto Meter Prodcuts Inc.

413 West Elm Street

Sycamore, IL 60178

(815) 895-8141

Mazda Competition Parts

7755 Irvine Center Drive

Irvine, Ca 92618

(800) 435-2508