Date: Tue, 21 Sep 1999 15:20:25 -0700 The early 93's came with 1.3 bar caps. Then Mazda had a

recall on the cooling system because it was suspected of

leaking coolant and starting engine bay fires. The recall had

some cooling system components replaced to withstand more

heat, plus the pressure cap was changed to a 0.9 bar cap.

I have also seen FDs with 1.1 bar caps, so don't know when

these where used - maybe between the original 1.3 and the

0.9 recall caps.

Anyway, I believe that 1.3 bar is too much pressure for the FDs

cooling system, and if anyone is using one, they should replace

it. It may also mean that the cooling system recall has not been

done on the car yet. If you suspect the recall has not been done,

call Mazda Customer Service at 1-800-222-5500 and give them the

VIN of the car. They can tell you if and when the recall(s) where

done.

The only draw back of the lower pressure cap is that if you run the

car hard, it may want to boil over. You should use at least 40 %

ethylene glycol (antifreeze) with distilled water and a bottle of

Redline water-wetter to ensure good cooling system performance.

If your antifreeze ratio is too low, you are also decreasing the boiling

temperature of the coolant, but getting slightly better heat transfer to

the coolant.

_________________

Date: Thu, 20 Nov 1997 01:24:40 -0800 (PST) Public service announcment

If you happen to be running a radiator pressure cap that says .9 on it,

you will want to upgrade it to one that says 1.1 (this is bar BTW, and is

equiv to 13psi cap, and 16psi cap)

I have seen quite a few .9 caps, and only a couple 1.1, and am not sure

when Mazda switched.. (coolant recall?)

_______________

Date: Thu, 20 Nov 1997 07:51:00 -0600 The caps were changed from 1.1 to .9 when Mazda did the coolant recall.

This is also the reason people started hearing percolating noises in their

cooling systems after turning off the engines. The lower pressure allows

the coolant to boil at a lower temperature, and the turbo area is very

hot. I never had this percolator sound until after the coolant recall.

Date: Fri, 30 Apr 1999 07:30:08 PDT I would agree with Kyle on going with the stock t-stat next

time around. According to Peter, for optimal performance the ECU

wants to see a water temp reading of no less than 180. Below

that point, the computer is still is warm up/protective mode.

Solenoids, secondary butterflies and injectors all work as if

the car was still cold. This is especially a problem on the

highway since temps will drop below the 180 mark and get pretty

close to 170. The difference in the minimum running temperature

on the highway at around 70 mph is only about 10 degrees, and

as it turns out, that's 10 degrees too cold.

_______________

Date: Fri, 26 Mar 1999 11:31:12 -0500 Since the AST issue has surfaced again, I am re-posting an AST article I

wrote last year. I have had no problems with about 4 track events so far.

The air-separation tank is in parallel with the radiator. Once the thermostat

opens, the hot coolant bypasses the radiator to pass through the tank, and is

returned, hot, to the waterpump inlet to re-enter the engine housing ports.

Its purpose is first to collect air/vapor in an upper, stagnant chamber.

Then by thermal expansion of the fluid and gas, it purges the collected air

into the vented overflow bottle by way of a 3rd hose that ends in the bottle

below the coolant level. Air bubbles rise to the top and vent to the

atmosphere. Upon cooling-contraction, coolant from the bottle is pulled back

into the system. A probable source of the air is a little leakage, from the

combustion chambers, by the o-rings.... mabe at cold start.

The coolant that flows to the separation tank comes from the top of the

thermostat housing, where a mini chamber is cast into the housing. The entry

into this chamber can be seen after removing the fill cap as a 10mm hole. The

only chamber exit is the hose to the separation tank. The purpose of the

mini-chamber is to encourage any air that is passing below, from the open

thermostat to the radiator, to rise up and be sent ( with coolant ) through

the small bypass line to the separation tank.

Problems With Tank Removal/Bypass line:

IMO, simple removal of the tank and splicing the lines is not recomended for

two reasons: First, it provides a bypass to the radiator that is not cooled.

But more importantly, it encourages any air that may collect at the top of the

housing to be pushed through the engine passages when the thermostat is open.

Remember that air movement to the separation tank was the primary function of

the mini-chamber at the top of the thermostat housing.

A Simple Fix:

I removed the tank and installed the new cap assembly at the thermostat

housing as others have done. But I also plugged the old connections (2) at the

nipples and removed the hoses. This eliminated the bypass, and created a modest

stagnant chamber at the top of the thermostat housing to purge out air as

before with the tank. It appears to work fine, perhaps this will satisfy both

pro-tank and anti-tank groups. As a final touch, I may insert an aluminum

baffle to help minimize turbulance in the 'new' chamber. With this mod, the

original cast mini-chamber traps coolant, so make sure it has some antifreeze

for winter climates. Ideally, a small hole in the bottom of the mini-chamber

would solve this little problem and add to the effective mini-AST volume.

____________________

From: Jose L. Corraliza [mailto:jcorraliza@snip.net] According to Dave (at KD Rotary), the stock AST has different chambers

and baffles which serve to separate the air from the coolant.

The aluminum ASTs are, in essence, a tin can with 3 nipples

welded on to it. Sure they don't split, but they don't remove

the air from the system as well as the stock tanks.

____________________

Date: Sat, 22 May 1999 00:33:54 -0500 > The cap on the filler neck should not be a pressure cap. The overflow Let me set the record straight here. Cooling systems are a specialty area

of mine, and I am quite positive that the following is correct:

In the strictest sense, both caps are "pressure caps" in that they hold

pressure in the system once it warms up. However, only the cap on the AST

is a pressure relief cap - the traditional type of radiator cap. You'll

notice the large spring that relives pressure, and the small disk in the

center that opens under vacuum to return coolant. The cap on the filler

neck part of the water pump/thermostat housing only acts to seal that

opening of the cooling system.

When ever your engine is running and the thermostat is open, there is

coolant moving through the AST. A small volume of coolant is tapped off

just past the thermostat and goes to the AST. Here it becomes nearly

stagnant, and any entrained air AND vapor bubbles rise up to the surface.

Coolant is then returned to the radiator, right next to the lower radiator

hose outlet (leading to the water pump inlet). Coolant that flows through

the AST bypasses the radiator, but that is the only way to get coolant into

the AST in the first place(there is the same large pressure drop across the

AST as the radiator).

The AST also acts a bit as a surge tank for the cooling system. When the

water pump accelerates (with the engine), there is a certain amount of lag

in getting the water flowing, due to its mass (needs to increase momentum).

This can cause the water pump to cavitate because it is trying to suck water

from a restrictive source - the radiator. Instead, it is able to draw down

coolant from the AST, which in turn can draw in from the atmosphere (through

the weakly sprung vacuum relief disk on the pressure cap). Actually, the

AST draws from the overflow tank, but in this transient surge role, it

really doesn't care, it just wants an easy path to get any fluid at

atmospheric pressure.

There is no need to replace the cap that goes on the water pump unless the

cap's rubber gasket goes bad. Also, most decent garages can test pressure

caps with a special pressure cap pump, but replacing an old one is not a bad

idea either.

Chris Hoke: sounds like your dealer put the caps on in the wrong spots. The

cap with the pressure number and spring loaded plunger should be on the AST

(the black tank by the intercooler - just to make sure there's no confusion

in what the AST is). The cap with only a rubber gasket on the back side

goes on the engine.

yes I am sure. I read the detail on the caps, plus just ordered

replacement caps for both from Mazda Comp. Of course both

need to be pressure caps, when block pressure get to point X it

overflows coolant to the swirl tank (round cap with black top).

this is the presurized overflow. this cap is normally higher

pressure than the filler neck cap to allow water with air bubble

to overflow to the swirl tank where the air separates from the

coolant. A line at the bottom of this tank goes to the radiator

to return coolant to the eng/rad when pressure drops a little.

If the swirl tank is full and pressure exceeds it cap rating, the

cap allow overflow to the NON pressurized overflow tank (a 3 part

system. Cooling in the block causing suction is supposed to

draw coolant back from the overflow tank to swirl tank to block

when operating properly.

____________________

From: les (lesd@earthlink.net)

While the elimination of the AST will simplify the under hood

plumbing, I think you still need to worry about how the system

will get rid of gasses in the system.

Notice I said gasses, not air.

It is my impression that the reason Mazda went to the effort of

making a fancy separation tank is because there is a chance

that even 'good' engines can leak tiny amounts of exhaust into

the coolant. Especially as the engine ages, and as the engine

components expand and contract at different rates because of

the different metals ( AL and iron ).

When you have pockets of gas in the coolant, there can be hot

spots that don't get the best cooling, and that can exasperate

the situation.

____________________

From: Shane Baker (sbaker@null.net)

The gasses are formed as a result of localized boiling, especially

around the spark plugs. At least, this is what the guy who used to be on

this list (and maybe still is) that designs engine cooling systems for a

living told me.

The other thing that the AST does that I never hear mentioned (I wish I

could remember where I read this) is act as a resevoir for the water pump

to draw from to avoid cavitation since the radiator offers enough

restriction to essentially starve the water pump in some conditions. I

read it fairly recently, so I should be able to it.

____________________

From: Steve Cirian

Dom wrote:

The failure of the aftermarket ones is worrisome, but I think we can ignore the

incorrectly fabbed ones (provided a person didn't get one of these...) in determining

if an AST should be used. And I think we can ignore the OEM failures, since my personal

debate was elimination vs an aftermarket one (see previous comment on worries about

aftermarket ones) .

I have gotten a couple of responses that say that one issue is that they need to burp

it regularly, especially at track events. This is not a complication in the sense of a

failure, but is still not a "perfect" solution. Plus if there are gas bubbles in the

coolant, you could get cavitation in the water pump. (that point assumes that the ASTs

really do eliminate all the gasses.)

____________________

From: Dave McAnaney (mcananey@yahoo.com)

I was running my car for years with the original

TriPoint AST with no problems. Being an engineer, I

felt that the RX-7 designers put the AST there for a

reason, so I did not eliminte it.

When I upgraded my intake and intercooler to the M2

large about a year ago, I lost the mounting point for

the AST and relocated it next to the intake. Bad move

- the new location was lower than the original

mounting location and air pooled in the filler neck

instead of the AST, causing the low coolant buzzer to

go off numerous times at the track. I was constantly

"burping" the system to no avail and noticing the

'sloshing water' sound in the heater core at startup.

So, I followed the majority and elminated the AST.

This worked fine on the street, but once I ran on the

track again I got the low coolant buzzer and 'puking

coolant' out the overflow. Again, I burped the system

numerous times but could not get the air out of the

system. I started thinking that I may have the

dreaded failing o-rings, but I did not have the other

symptoms (white smoke on startup, rough idle, oil in

the coolant, etc.).

I decided to un-eliminate the AST and mount it in

front of the water pump at the same height as the

filler cap. So far, so good. Although I have not

driven the car on the track since reinstalling the

AST, I have not noticed any sloshing water sounds at

startup and the coolant level seems to be

leveling-off. We'll see in a couple weeks at the heat

of Thunderhill.

[opinion] ____________________

From: Eull, Timothy R. (timothy.eull@honeywell.com)

It's interesting that you should post your question at this time. I live

here in Phoenix AZ and recently attended Sevenstock in Irvine CA. Prior to

my departure, I installed aftermarket water and oil temp gauges (water temp

plumbed on the "flat" area of the filler neck, and oil plumbed via a

threaded banjo bolt just under my filter).

Anyway, on the way to the event I saw operating temps (freeway cruising at

80 mph) in the 210 to 220 range and a spike near 240F going up a hill into

Palm Springs (ambient ~105F). Anyway, the entire time my stock gauge did

not budge from the "middle" reading.

Once I arrived at Sevenstock several people saw that I had installed the M2

AST removal kit and expressed concern that my system might have air bubbles.

Indeed it did. Unfortunately when it came to proper burping and filling of

the system (including removal of the manifold hose and topping that off as

well) I was totally in the dark. Also, the folks from Pettit strongly

discouraged use of the elimination kit for the very reason you suggested

(eliminating the system's ability to bleed air from the system).

Anyway, after winning a TriPoint AST at the event, I installed it that night

in the parking garage of my hotel with the few crude tools I had brought

with me, properly filled and burped the system, and headed for home the

following day. On average the gauge readings I observed were 10 degrees

cooler, given similar conditions, than the trip out.

Does this mean that the car will run cooler on average with the AST versus

without? I'm not sure. The AST definitely gives you additional coolant

capacity, but I've got to believe that a properly filled and bled system

that eliminates as much air as possible will probably work just as well. My

operating environment is one of the most extreme in the U.S.! For now,

I'll stick with the aftermarket AST.

____________________

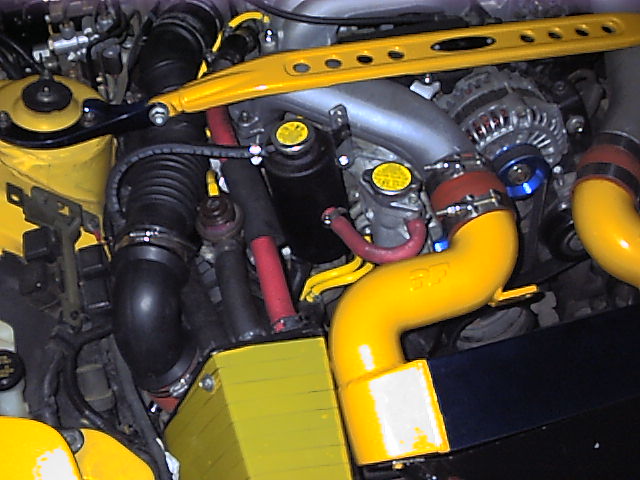

Date: Fri, 20 Jul 2001 07:57:46 -0600 I have a Tri-point AST. It was mounted on the bracket on the PFS

intercooler (which certainly looked like it blocked a lot of the air

flow through that). It also had to have very long lines going to and

from it.

Last month I installed the efini "Y" pipe, and removed the air pump

(as I have no catalytic converters). I used the Greedy pulley kit to

get the belt length issue resolved. I moved the AST to where the air

pump was, and fabricated an aluminum bracket (off the air pump

mounting holes). I put a hole every 1/4" or so up the bracket so I

could mount it as high as possible. The lines to/from the AST are now

very short. The PFS intercooler now has a clear cavity behind it

(room for fans/a fan). The AST works very well in this position (the

filler neck on the engine is now always almost completely full of

coolant).

I think this is the best/most effective mod. (or series of mods.) I've

ever done to the car. I also fab'd an aluminum bracket to support the

plastic air tank on top of the engine (mostly for looks - it was

supported by the "Y" pipe output plastic pipe support - I removed that

ugly heavy part).

____________________

Date: Fri, 20 Jul 2001 10:42:43 -0700 Yeiks! The AST vs. non-AST debate is beginning to look like the venerable synthetic

vs. nonsynthetic oil debate. No real hard data and no likelihood of ever getting any.

Just lots of anecdotal evidedence and opinions. So, here is my opinion with absolutely

nothing to back it up. 8-)

First, water (or coolant in this case but lets stick with water) has air dissolved in

it. You can't see it, but its there. For example a glass of water sitting on your kitchen

counter contains approximately 2% air by volume. If you heat up this glass of water to

lets say just below boiling about half of that air comes out of solution in the form of

tiny bubbles. Pressure changes act in a similar, but opposite way - higher pressure more

dissolved air, lower pressure less dissolved air. But, since on the third gen there is

only a 13psi difference between a pressurized coolant system and an unpressurized system

this effect is small compared to the large temperature differences experienced by the

cooling system.

Well, lets get to the meat of this editorial, my guess is that the AST was not put

there to remove pockets of air that remain in the system after filling it (which, in my

experience, it doesn't do), but it was put there to reduce the concentration of dissolved

air in the coolant. How does it do this? Remember, in the previous paragraph when water

is heated (for example, as it passes through the engine) dissolve air comes out of

solution as tiny air bubbles which are so small they are swept along with the flow. With

an AST, these tiny air bubbles are removed before the coolant goes to the radiator.

Without the AST the coolant and air bubbles go into the radiator, the fluid is cooled,

and some of the tiny bubbles are reabsorbed into solution before going back into the

engine, starting the process all over again. In any case, without the AST after shutdown

when the engine cools all the tiny bubbles go back into solution.

So, as I see it there may be two concenquences with removing the AST and having a high

level of dissolved air in your cooling system. The first one is corrosion. Air has oxygen

in it, dissolved oxygen, especially at elevated temperatures, is very corrosive. Sure,

your antifreeze keeps this in check for the most part, but only if you religiously change

it once a year. Lowering the level of dissolved oxygen certainly could help reduce the

amount of corrosion in the cooling system over the life of the engine. The second problem

with air dissolved in the coolant is efficiency. Remember, as the coolant is heated by the

engine the dissolved air comes out of solution in the form of tiny air bubbles. This air

bubble/coolant mixture is not as efficient at removing heat as a purely liquid coolant

mixture.

In conclusion, IMHO, eliminating the AST may result in a slightly increased rate of

corrosion in the cooling system and a slight decrease in cooling efficiency. Since, most

people will not keep their cars long enough to notice the former and a cooling system in

good shape has enough excess cooling capacity to negate the latter, eliminating the AST

will not have any immediate adverse effects on a well maintained cooling system. But, if

you don't religiously maintain your cooling system, need every last percentage of cooling

capacity you can get, or intend on keeping your car forever, it may be a good idea to keep

the AST (but, certainly not the stock AST).

____________________

from les (lesd@earthlink.net) Stock OEM Ast's have no baffles either.

I've sawed one apart before.

from les (lesd@earthlink.net)

I don't think localized boiling would be it.

Boiling water makes water vapor(steam), not air.

High school physics.

As soon as the water vapor (steam) cools, it collapses

right back to liquid again, leaving no bubbles.

When the engine cools, there would be no bubbles because

of any kind of boiling.

I agree with another poster, there is trace combustion gas

leakage past the O rings. The AST is designed to purge

that ongoing process.

____________________

From: tworx7s (tworx7s@zbzoom.net)

Simply put one of those vent-lever caps on the remaining filler neck,

instead of the generic non-thermo cap, which is basically just a lid. You

can then use the vent lever to "burp" the system, but if you follow the

proper procedure for filling the cooling system in the first place, you

shouldn't get enough air in the system to cause potential danger. It would

essentially become like any other system. HOWEVER, if you race your car and

it repeatedly heeats up and cools down, you will find you'll need to burp it

more often... there, there now, that's a GOOD baby :-)

____________________

from Max Cooper (max@maxcooper.com)

The plugs you use to eliminate the AST are points of failure themselves. I

popped two of those HELP! brand rubber caps before I switched to short

sections of hose with bolts clamped in the ends. They are ugly, but they

work. I am looking at some caps from McMaster-Carr or perhaps installing a

hose from nipple to nipple with a flow restrictor in the middle.

I agree that the simplification is nice.

I lost a motor last year, but I do not think it was related to the AST

elimination in any way. The new motor has been fine for >10,000 miles with

no AST.

I do wonder sometimes why the car had one in stock form. Mazda did a lot of

work to eliminate weight and unnecessary parts. They even moved the coils so

the spark plug wires could be short and thus light. If the AST wasn't good

for something, it would not have been there. My car seems to be fine without

it, but these thoughts do nag me sometimes.

The car should be able to expell excess gas through the overflow tank. I do

not ever have to burp the coolant. It has been more than 8,000 miles since I

opened the filler cap.

____________________

from dbeale (dbeale@harddata.com)

Those who have removed it, do still have one, sort of. The space on

the engine filler neck becomes the AST. Rather small, but perhaps ok.

____________________

From: Shane Baker (sbaker@null.net)

You may agree with that person if you like, I'm going to stick with the

person who designs cooling systems for a living :) I'm sure many of you

know whom I am talking about, I just don't like to bring innocent

bystanders into a thread that they didn't ask to be in.

Not another 'high school physics' debate... please... I give up

:). (Sorry, just kidding, really... it just seems that somehow it is

always me who is on the receiving end, whether it be someone trying to

convince me that tire traction has nothing to do with contact patch size

or whatever... it's kind of funny that it always happens to me).

Anyway, what you said about the steam makes sense, however, the cooling

system is not filled with pure water. The chemical interactions that

might take place at high temperatures with ethylene glycol and water and

the various metals and whatever else might be in there are not necessarily

going to revert at cooler temperatures. I'm not saying that I know what

these interactions are or that they even happen, just that it's easy to

suppose that they might. If nothing else, I can say that water is self

ionizing and produces hydrogen ions (and hydroxide), some of which would

have to produce a hydrogen gas. I am willing to go out on a limb and

say, with absolution, that this is not the gas that we are trying to

eliminate (I'm not a chemist, but I recall that this is not a 'popular'

reaction... good thing or we'd be in trouble) and I'm only mentioning

because it suggests that, while high school physics provide a valuable

foundation, they are pretty much never adequate for completely explaining

the real world... and it's pretty much the only thing that I know on

the subject to make that point :). Like you said, we're concerned about

'gases', not 'air'. The question is, what does a boiling ethylene

glycol/water/whatever solution produce? I'm not trying to condescend or

anything, just further the discussion.

The exhaust gas theory is interesting, and there may be some merrit to it,

I don't know.

According to 'cooling system guy', the orifice sizing of the AST is as

important if not more important (I'm recalling from memory, don't blame

him if I screw it up :) than the AST tank size. The orifice sizing will

control the flow through the AST to both keep the fluid relatively

stagnant in the tank but also (probably more importantly) to keep too much

fluid from going through it because it is basically a route for coolant to

travel that bypasses the radiator.

I tried to find that text that I read suggesting that the AST actually

helps stop cavitation under some circumstances, but I didn't. I'll keep

looking though.

____________________

Date: Wed, 28 Jan 98 19:21:00 -0500 >As I recall some of you have put Pettit Racing aluminum coolant air I have the pettit coolant tank.....hasn't leaked yet! and I can't see it

exploding since its aluminum and not plastic with a seam like the

stocker...

________________

Date: Wed, 24 Mar 1999 09:11:07 -0500 I purchased the Pettit AST and it came with new clamps, a new

cap, and the tank.

I then needed additional hardware, (1-10mm bolt & 2-10mm nuts) and a

mounting bracket.

The welds on the tank looked OK, definitely hand welded.

The finish was very nice.

When I dropped it in, the mounting tab that was welded to the tank was

1" too low and about 1/2" off toward the firewall.

Since it was 8:30 on a Wednesday night I ran up to get the hardware,

hacksawed, drilled, and bench ground a 1/8" thick aluminum piece that I

found in the garage.

Fortunately I anticipated such an event, so I was up to the fabrication

work and the holes & slot lined up the first time.

This really was not a big deal but ANY other after market whatever that

I have installed has ALWAYS had an installation sheet to warn of these

things.

I understand that Pettit possibly switched vendors, or the FAB house

accidentally grabbed the wrong revision drawing, but that doesn't help

someone who is hacksawing a chunk of aluminum in their garage at 9:00 on

a Wednesday!

________________

Other people said as well that Pettit has fixed some of the mounting

issues as well as the requirements for "extra" parts or fabbing your own

bracket. I would call them and ask for clarification on it. --Steve

________________

Date: Tue, 03 Aug 1999 19:41:44 -0400 I and many others have used the Pettit AST tank for years without

problems. Std radiator cap works with it or you can use the

fancy vented/locking cap it comes with.

The only negative is the bitching about its cost - as is clear

from the recent posts nothing is really as simple as it seems and

if your cooling system screws up it costs you the engine.

My opinion, the AST performs an important function on the FD and

should not be eliminated. Others with equiv. experience to me

have have eliminated it and have a different opinion. Take your

choice.

_________________

Date: Mon, 22 Mar 1999 11:30:39 -0800 Replacing the stock AST is a wise move. I was always planning on doing

so but never got around to it until it was too late.

One morning I startup my 7 only to hear the coolant buzzer go off.

Popped open the hood and saw coolant all over the AST. I ended up

replacing my stock tank with Tri-points aluminum tank. I found

Tri-points to look better than Pettits. Tri-points also uses the stock

(they include a new one) AST cap instead of that standard radiator type

cap. No bracket needs to be fabricated as with Pettit's. Tri-points

bolts right up at the same stock location. The only thing you will need

that was not included (at least with mine) is a small nut to put on the

existing bolt.

One thing that was fixed by changing the leaky AST to Tri-points is the

"water rushing" noise that I used to hear under the passenger side dash

whenever I started up my 7 or sometime during idle was gone.

________________

Date: Fri, 26 Mar 1999 08:05:10 -0700 I just got my aluminum AST from Tripoint. It comes with the Mazda

pressure release (with the spring - .9 bar) cap. Wish I knew that,

could have saved the $28 Can. for the new cap I just bought. The tank

is black anodized, and looks very similar to the Pettit unit in shape

and size. Very well made, nice heavy mounting tab, comes with 3 ss

hose clamps. Don't plan soon on building these yourself. The cap

flange is intricately machined, and is actually better made than the

original Mazda one. The welds on the three spigots are first rate.

I've never seen the stock components under my hood (PFS intercooler

and cold air intake were on the car when I got it), but the tank has a

1/8" rod sticking out the bottom. I presume this is inserted into a

grommet or something on the stock intercooler parts? My only concern

is the nylon fitting on the overflow spigot. The hole in it is only

about 1/8". If I ever boil the coolant that sucker is going to be

"tested".

________________

Date: Wed, 7 Apr 1999 16:53:40 -0700 I talked to Mark at TriPoint Engineering about the caps

that come on their AST. The stock 3rd gen pressure

cap (Mazda P/N: N3A1-15-205A) without "ears" will

work, as well as an older style cap (Mazda P/N:

D316-15-205) with "ears". Both are 0.9 Kg/cm (12.8 psi),

stock rated caps (do NOT put a higher pressure cap than

that on).

TriPoint usually sends their AST with the "eared" cap

because its a little easier to take on and off, but

apparently you can have them put either on it for you.

Also, when you go to replace it (in about 1 yr), you

now have two factory caps to choose from, from your

"friendly" Mazduh dealer.

________________

Date: Thu, 8 Apr 1999 08:13:02 -0600 My Tripoint AST came with the "uneared" cap (must have met up with

Mike Tyson).

A word of warning for those with the PFS intercooler, who have ordered

the Tripoint AST. It doesn't quite fit properly. If you still want

to install it, you have two choices:

1.Drill a new hole in the PFS intercooler AST mounting tab (you have to

move the hole closer to the tube the tab is welded to).

2.Raise the AST so its tab rests above the PFS tab. Then make

a U shaped piece to join the two (it sits over the two tabs, and when

you drill holes in the right places in it you can bolt the two tabs

together using the U shaped piece).

I'm using the second method, as I believe having the tank higher is a

GOOD THING. This will force the "bubble" of air in the system to

migrate to the AST, where it will always be forced into the overflow

tank. BTW, I did check to see if the hood will clear it - it will.

_________________

Date: Thu, 8 Apr 1999 11:29:52 EDT I also had some fit difficulties w/ the PFS IC, but by slotting the hole (in

the AST, not the IC) about 3/16" in towards the body of the AST, it fit like

a charm. The AST wedges tightly against the IC discharge pipe.

_________________

Ken posts regarding problems some of the older Tri-Point ASTs. Anything

you buy now should have these issues fixed. Scott (Robert S. Ulen) posts

further down on measurements he made on his AST. --Steve

Date: Tue, 3 Aug 1999 22:45:21 EDT A growing body of evidence points to problems with some but not all Tri-Point

Air Separator Tanks (AST's). Specifically, the dimensions of the cap

housing on some Tri-Point's AST's do not meet SAE standards. This can result

in the AST's cap not relieving the cooling system's pressure at the cap

rating. (In my case, the pressure was not relieved by a 13-lb cap until

20-22 PSI was reached.)

One way to determine if your Tri-Point AST meets the SAE standard is to

measure the distance from the top lip of the cap housing to the top of the

inner hole. The SAE standard for this distance is a range of 15.53 to 16.03

mm. (My Tri-Point AST measured 14 mm). To make the measurement, put a

straightedge across the top of the cap housing and drop a piece of paper down

until it reaches the top of the lower hole. Then mark the paper, remove it

from the cap housing and measure the distance. It will take just a few

minutes to do this. For a reference point, this distance in the OEM AST

measures 16 mm.

The second way to evaluate your Tri-Point AST is to conduct an actual

pressure test on your cooling system. The pressure tester would be mounted

on the Filler Cap housing to determine the pressure at which the AST cap

activates. This, however, is not the best of tests because some caps have

been shown to provide relief at the rated pressure even with a non-SAE

compliant AST. Call these the "forgiving" caps. Therefore, this pressure

test would only show that the AST only functions with the cap presently in

use. Replacing the cap could result in the purchase of an unforgiving cap

and over-pressurization of your cooling system.

_________________

Date: Tue, 3 Aug 1999 10:37:24 -0700 I wanted to email you guys, and let you know what I have found so far about my

TriPoint AST. It seems like the 3 of us are the most involved with this possible

overpressure issue. This really concerned me, so I jumped right in to find out

what is happening with my car's cooling system. The last thing I need is a failed

O-ring, or some serious problem associated with coolant overpressure.

Last night, I did very careful and many measurements (for technique and repeatability)

of my stock AST and the TriPoint AST. This is what I found:

Stock AST

- ----------------

TriPoint AST (mine)

- ----------------------------

Measurements of Stock 0.9 Mazda Pressure Cap (no ears, no markings, almost new)

- ---------------------------------------------------------------------------------------------------------------------------

Conclusions

- ------------------

This analysis says that the stock cap and the TriPoint AST should work fine together. The

"pre-load" of the spring plunger is the same, which means it should relieve at its rated

pressure (13 psi). The "pre-load" is a very important aspect of the integrated design. If the

pre-load is more, then the required pressure to move the plunger off the seat would be higher

because of more force required to move the spring.

Ken, BTW in one of your posts, you mentioned something about a "thermally activated spring". Actually, the spring is just a spring, and it is not thermally controlled like a thermostat.

The plunger only moves due to pressure, and is solely dependent on the pre-load of the

plunger spring, and the spring constant (which in linear in this case).

Dave, in your post to me, you said your original pressure cap had the black sticker, and had

"1.3" printed on the top. Wow - that is a 18.5 psi cap. It sounds like you car has not had

the coolant safety recall. If the top fitting on your filler neck is black nylon material, and not

aluminum it definitely has not been done. Call Mazda Customer Service (1-800-222-5500),

and give them your VIN off your car. They can tell you if their records show the recall or not.

Anyway, tonight I am borrowing a coolant system pressure tester. My plan is to install the

tester/gauge on the filler neck, then start the car and record system pressure vs. coolant

temperature. After the engine is totally hot, I plan on monitoring the pressure while the

coolant goes through its fluctuations (195 to 230 deg F) during various fan running scenarios.

Then, after I shut down the engine, I will monitor coolant temp (hot soak to approx. 245) and

pressure during cooldown.

Ken, if you actually measured 14.0 mm as the neck depth on your TriPoint AST, then I would

say you got a bad one. I talked to Guy at TriPoint yesterday, and asked him what the design

dimension for the neck depth was. He said that the neck part of their AST is designed and

manufactured by a reputable radiator manufacture. If this is the case, then I would assume

that some knowledgeable engineering was put into the neck design. Based on the measurements

I did on my TriPoint AST, it looks like the dimensions are very close to the SAE specs that

Ken gave in one of his posts. Anyway, TriPoint seems to be looking into this issue, and it

maybe entirely possible that they got a bad batch of neck made by their supplier.

I will try to pass on the pressure vs temp measurement I plan on doing tonight. That will be

the true test on the function of my AST. Hope this information help get this issue resolved.

_________________

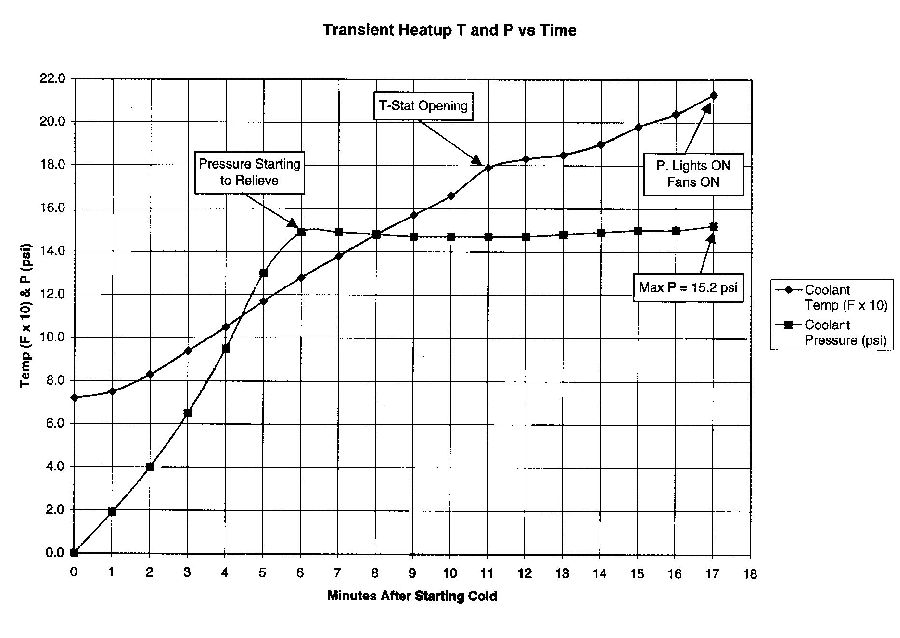

Date: Wed, 18 Aug 1999 15:53:41 -0700 COOLING SYSTEM PRESSURE MEASUREMENTS I finally had a chance to conduct what I call "dynamic" pressure

testing on the coolant system with the TriPoint AST using the

supplied OEM Mazda 0.9 kg/cm^2 (12.8 psi) pressure relief cap.

I did this by installing a temporary coolant line (replacing the

stock one) between the filler neck nipple and the AST nipple.

In this line was installed a calibrated pressure gauge that was

"T'"-ed into the temporary line. This allowed me to monitor the

pressure in the coolant system as it heated up, went through

various fan operation modes, and during engine hot-soak and

cooldown. Coolant temperature and pressure data was measured

and recorded during these tests.

The basic results are as follows:

During warmup, the coolant pressure increased relatively

rapidly upto approx. 15.4 psi maximum as the coolant expanded.

Coolant pressure remained at 15.2 ~15.4 psi until the cooling

fans ran for the first time @ 210 deg F (parking lights where on).

When the fans came on, the coolant pressure would drop to

approx. 6 psi at fan shutoff at ~195 deg F. Note: the temperature

monitor was a Type 'K' thermocouple mounted on the filler neck

housing near the ECU and fan switch sensors.

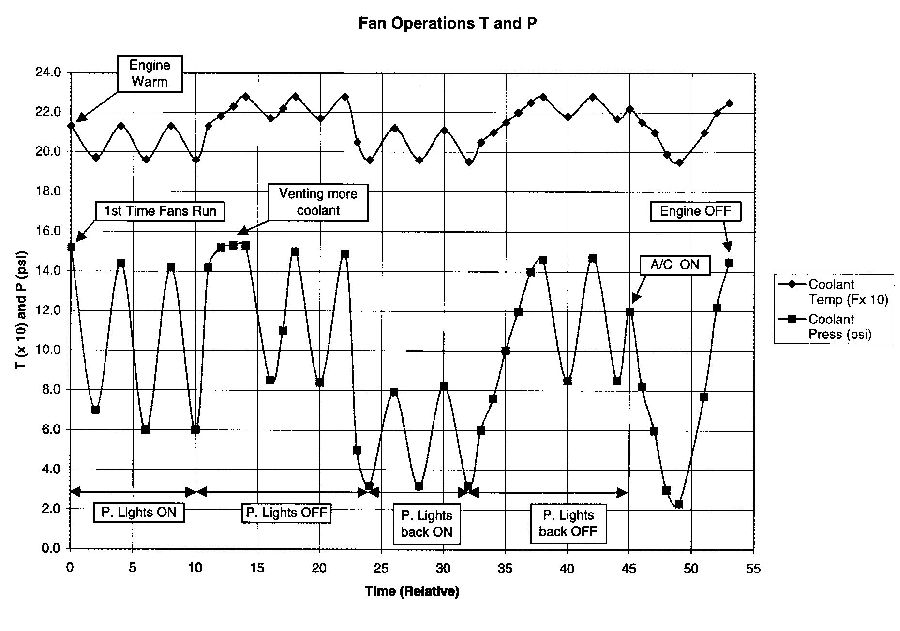

Parking lights where turned off to allow the coolant temperature

to go to ~228 deg F until the fans ran again. This caused the

pressure cap to vent alittle more coolant since the system had

not been this hot yet. Vent pressure was 15.3 psi. When the

fans would run, the coolant pressure would cycle between 15.0

and 8.5 psi.

Parking lights where again turned on to bring the fan cycling

back down to between 210 and 195 deg F. This caused the

coolant pressure to cycle between 8.0 and 3.2 psi. This make

sense, because more coolant was vented when allowed to go

to ~228 in the previous step. Once coolant has left the system,

it can not return until the cooling system cools enough to cause

a vacuum and pull coolant back from the overflow tank. This

starts to occur hours after engine shutdown as seen during the

hot-soak and cooldown portion of the test.

At one point, I enabled the A/C which caused the fans to run

continuously and bring the coolant temperature down to ~192 deg F.

This caused the coolant pressure to dip to a low 2.3 psi. Note: feel

the pressure in your AST hose sometime after the car has been hot

(city driving for awhile) and fans have ran awhile with A/C on. The

hose will have little pressure in it.

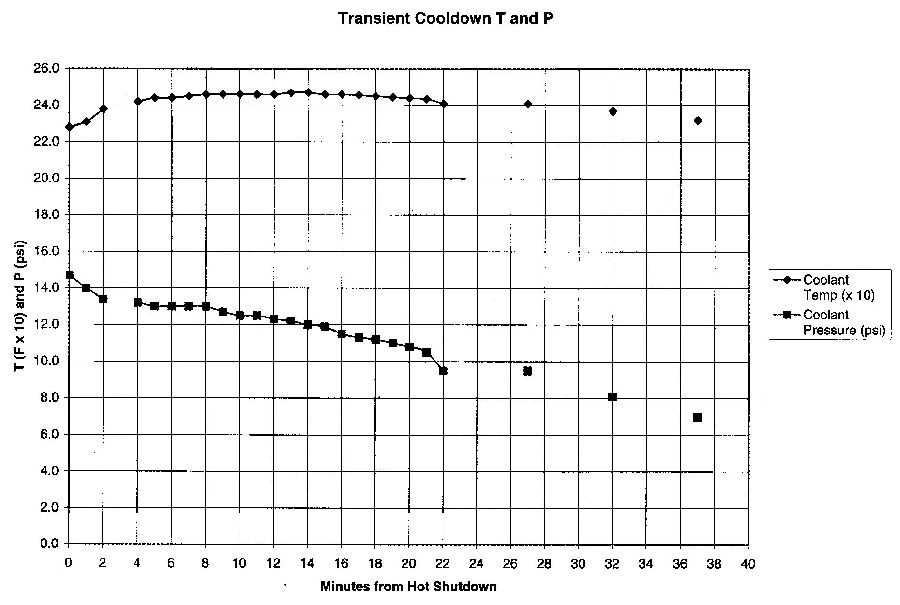

After the fan operations test, I shut the car down when it just

reached 228 deg F to get a max "hot soak". I was expecting the

coolant pressure to go back up to 15.4 psi and vent some more for

the first 20 minutes or so, but surprisingly the pressure started

dropping almost instantly. Reason for this is because the overall

"bulk" temperature of the system must drop, even though the filler

neck area of the engine was increasing. Good news, is that the

cooling system is not under full pressure during a hot soak.

Conclusions

The TriPoint AST vents slightly higher than the rated 0.9 (12.8

psi) cap, but not too far off. If it was more than 16 psi I would get

concerned. I did some more measurements of the TriPoint AST,

and found that the "effective pressure area" (area that the pressure

of the coolant pushes on the cap spring valve) is approx. 18 %

smaller than the stock AST. This causes more pressure to be

required to produce the same force on the valve spring. Note, my

TP AST had a 15.5 mm seat-to-seat dimension, which is within SAE

specs. Both the seat-to-seat dimension (determines relief valve

pre-load) and the effective pressure area play a very important role

in what pressure the cap will relieve pressure. BTW, 12.8 psi X

1.18 (18% increase) = 15.1 psi (close to what I saw). I also did

"static" pressure tests with air on the TP AST before doing the

"dynamic" pressure tests, that basically gave me the same ~15.0

psi vent measurement.

Running the dynamic tests also showed some interesting facts that

the coolant pressure in an FD (or any car with electric fans only) will

have large coolant pressure fluctuations as the bulk temperature of

the coolant system changes due to fan operations.

________________

From: Hoskinson, Jeff/EXEUG3 (jjhoskin@pscnet.com) Well, I finally bought an AST, based purely on the wisdom of the list. I

ended up buying one from from Perfomance Warehouse. I received it on

Tuesday or so. My first impression was, it looked OK, quality was OK, but

there were things to be desired.

Downside.

Upside.

It has a nicely CNC'd filler neck. It could be highly polished. The

weld look OK. It would probably work OK if the filler neck dimension was in

spec.

So I wrote Mr. Irvine, and he said that I was the first to complain (maybe

I am ultra picky, maybe I got a bad one?). He also said that his was better

quality than his competitors. He would charge me a 30% "restocking fee"

if I wanted to return it.

Any suggestions? So I am thinking of getting the "new and improved"

Tri-Point one now. I will sell this AST to anyone for $70, it is all Al,

sorta polished.

Date: Tue, 08 Feb 2000 15:51:28 -0800 SR Motorsports offers two radiators, the Mazdacomp which is

50% ($617) larger and their own version which is 100% larger ($695).

_______________

Date: Tue, 8 Feb 2000 15:37:51 -0600 Ray had these proprietary radiators

built to his specs. The quality is the same as the Mazda Comp units, but the

core is a full 2" compared to the 1 3/8" Mazda Comp piece.

The SRX7.com radiator is the thickest core unit on the market. For full

efficiency, be sure to block any openings in your ducting to force all the

air through the radiator. Many people overlook this simple trick.

_______________

Date: Thu, 30 Mar 2000 22:41:25 -0700 (MST) There's been some interest in info about the SR Ultimate radiator,

here's my $.02, I put mine in about 3 weeks ago.

Absolutely no fitment problems with the radiator itself, other than

bending the radiator support tabs below (really its no big deal, took 2

mins with a pair of pliers). Very easy to install, took me 2.5 hrs (and

I'm not a fast mechanic) including removal of the old radiator. Overall,

I'm very impressed with the quality of the radiator.

The only place I had slight fitment

problems are the I/C and intake. I have the M2 intake and the M2 large

I/C. The intake is pretty easy, you just have to bend one of the tabs at

the bottom so it goes around the fan bracket instead of inside it.

The IC is a bit tougher. It's not the I/C that causes the problem but rather

the ducting. With the increased depth on the bigger rad., the ducting

stuck up too far to allow the hood to close properly. I ended up

trimming the duct to allow it to press downward against the I/C when the

hood closes. That, and I now carry my hood prop rod in my trunk:-).

I don't know if this would also apply to the medium I/C, but I would think

so since they are such similar designs. If I made it sound complicated, I didn't

mean to, it really wasn't that bad.

I've got some

pics of all

this stuff on my site. Let me know if there are any other Q's.

__________________

Date: Mon, 3 Apr 2000 18:59:01 -0400 I recall someone noted the extra 1 inch thickness offset went up, not down.

Fine for the SR hood-hugger IC, but not so good for other brand large stock

mounts, esp the ducting.

PF says healthy stock rad is adequate ..... mabe in perfect shape. The

original mazda comp was 1.38 vs 1 inch stock core, but was narrower and had

less height, so core volume was only about 25% bigger.

What is needed is 1.38 to 1.5 inch core, with front area same as stock, and

all offset downward. Any bigger is overkill, imho.

__________________

Date: Sat, 11 Sep 1999 09:34:39 -0500 For you folks looking for replacement radiators... Ray Lochhead at SR

Motorsports (www.shaneracing.com) has the MCP unit listed at $615. You

might want to check that out.

I got mine from MCP direct and had no fitment problems other than a

little snip of the side piece. It was so trivial, I wouldn't call it a

problem.

_________________

Date: Thu, 7 Jan 1999 19:07:51 -0500 Pettit Racing will have a 50% larger radiator for sale in a few weeks, it

will also cost less than the current 33% larger unit. Jeff informed me the

50% unit will retail for $600. Those interested should reserve one now

before all will be spoken for.

__________________

Sandy lists places to get aluminum radiators. --Steve

Date: Tue, 27 Jan 98 07:09:52 -0500 >I am looking for a racing aluminum radiator for my FD. Mazda Competition, Griffen Radiator (on WWW) and Fluidyne (on WWW). None

are inexpensive (ie. all are over $500). On the other hand, an engine

rebuild is far more costly. Best intermediate step is a separate water

temp guage which tells you actual operating temp (critical at road race type

track events).

_________________

Date: Fri, 1 May 1998 02:28:20 -0700 (PDT) Sandy was nice enough to instruct Mazda Comp to ship his $500+ radiator to

me...I think I will just have to keep it :)

Actually he had it sent to me so I could verify that my ducting would in

fact work with it.

I was a little dismayed to see that it is an almost exact copy of the

stock radiator. I was hoping they had increased the width of the radiator,

taking up the space normally occupied by foam, with core space. What they

did was replace the foam with a piece of aluminum. Its possible they had a

reason for this, and will find out in the morning, as I am planning on

fitting it in the car then.

I did pull my stock radiator out of storage, unbolt the fans, and got out

the dial calipers. The stock core is just about 1" thick, and the Mazda

Comp radiator core is 1.5" thick. The end tanks are physically 2" thick,

where the stock end tanks are 2" thick only at the crimp locations, and

about 1.6" thick elsewhere.

I personally will most likely have my own radiator fabricated which can

take advantage of the lack of an A/C condensor, PS lines, etc, but would

suggest that most people use the Mazda Comp one, as it's definately a large

step in the right direction.

________________

Date: Fri, 23 Apr 1999 17:40:58 -0400 (EDT) The Derrick Sport radiator from Cork Sport is just as good as the

Mazda-comp but costs less. I haven't recieved mine yet, but I've been told

it should bolt right up.

________________

Date: Thu, 24 Jun 1999 09:42:52 -0400 The newer MazdaComp radiator, from Anthony Woodford Racing, has contoured

endplates that tend to follow the edges of the frame rails better than the

previous model(s).

Despite the new design, I still put in vertical ducts on

either side of the radiator. This effectively keeps all intake air going

through the radiator, instead of leaking around the edges. It also helps to

get some of that foam weatherstrip from a home store and seal up the areas

that the vertical ducts (mine are plastic - so not rattling against the

radiator or chassis) don't seal.

I went a bit more extreme though, and

removed the PS and AC equipment, so no condenser and PS coil in front of the

radiator. I have a big hole in the engine bay that allows me to see the

steering rack and road beneath the car. The hot air from the MazdaComp

radiator spills into this area and exits the car.

Cooling temps with this

setup is 185-195, and at WOT climbs to 210 or so. I ran up to 210 degrees

on the dyno, w/ a small low-CFM fan blowing into the front of the car.

Pressing the AC button on the dash still activates the fans, so temps go

right back down to 195 at idle or in traffic too. Temps were measured using

an Autometer electrical H2O gauge.

________________

Date: Sun, 02 Apr 2000 19:46:37 -0700 I went to the International Auto Salon at the Fairplex in Pomona, CA

today. This event is a big car show with lots of both cars and vendors.

I was very impressed with the range of products and vendors.

* FLUIDYNE - a new radiator for

the FD is listed as being scheduled for

release in April 2000 in their catalog and price list. An FC radiator is

listed in the catalog for July 2000 release. I wish I would have talked

to them now, oops!

_________________

Date: Mon, 3 Apr 2000 21:47:29 EDT I just called Fluidyne and they will have a drop in radiator ready for 3rd

gens by the end of the month. List price will be about $530.00. I asked

about a possible group buy and he seemed to like the idea. Just another

option. Their number is 800-685-0123.

_________________

Date: Wed, 26 Mar 2003 09:50:06 -0500 Here is some actual rad data from a comparison I did a couple years ago

Stock rad - plastic end tanks, 1" thick, 54 core rows with 105 fins/foot of

core

MazdaSpeed - all aluminum, 1 1/2" thick, 54 core rows, 110 fins/foot of core

Koyo - all aluminum, 2" thick, 64 core rows, 112 fins/foot of core

From the above it should be clear that moderate improvments will occur when

going to the MazdaSpeed unit, everything else kept equal. Increasing

thickness of a rad helps but there are diminishing returns for increasing

thickness same as there are for increasing thickness of an IC or any other

exchanger. More core rows is better and a combo of more core row and

thickness is better yet. That's why the Koyo will cool the best. Fit

issues need to be considered- the 2" thick Koyo can cause issues with fans

and other stuff plus what has already been noted. The MazdaSpeed should

always be considered as a stock replacement because it gets rid of the issue

of failure of plastic end tanks- plastic isn't really a suitable material

for end tanks any more than it is for ICs- its only justification is that it

is cheap. The MazdaSpeed is prettier and a better fit.

But don't expect a rad to be a miracle cure for track use- it is not as many

of us know from experience. As W notes, sealing is more important. The 3rd

gen motor with thermostat in place is flow limited for cooling. Drilling a

few holes in the t-stat, an old trick, works well and allows me to keep my

T-78 running 15 lbs boost and an 8500 rpm shift point at 205 degrees or less

on even sweltering summer days on track. 190-200 is more usual. Mine is a

TRACK ONLY vehicle (fuel cell, full cage, etc) so if you want to consider

this for a street machine that sees a lot of track use, note the following.

Warmup time is increased a lot

In cold weather, operating temps may be so low that you will need to block

some airflow to the rad (I cannot get over 165 in winter track sessions

otherwise)

Kiss emissions control goodbye. The real reason for the 3rd gen operating

temps on a stock vehicle has to be emissions- no sane engine maker goes to

226 fan temps unless forced to. Cooler motors emit more unburned HC, all

else equal (which it rarely is)

Contrary to what has often been said, lower temp thermostats cannot and do

not reduce operating temps by the fact that they open at a lower temp. Once

a t-stat opens, that's the end of its contribution to temp control which is

a warmup function, not an in use, regulating one. Some low temp thermostats

I've seen have a larger volume opening (height of opening and cross section)

so allow more flow - that is very probably the reason why some see reduced

temps with them in use.

(My car) also has the CWC oil coolers and, as reported by others, oil temps

track water temps with that setup.

_______________

Date: Tue, 4 Apr 2000 14:48:44 -0400 Below is a quote I received last night from

www.radiatorwholesalers.com

for a stock replacement radiator for

my 93 Auto.

I was asking for a possible upgrade, but all they had was the

stock replacement. The part number is 2067 and the cost is $149.34 shipped

to your door. Keep in mind this quote is for an auto, but they probably

have one for the manual as well.

If you get a used one, have it cleaned thoroughly.

_______________

Date: Mon, 14 Feb 2000 20:41:59 -0800 The AT Cooler was integrated into

the radiator on my 93 auto. I installed the Shane Radiator and an

aftermarket AT cooler.

Date: Mon, 23 Feb 98 17:43 PST For anyone interested in replacing worn, aged, and/or petrified

radiator hoses, I have come across the following.

Pegasus Racing (800.688.6946) stocks SAMCO Silicon Radiator hoses

for 3rd Gen RX-7s. The 2 hose set is a direct replacment for the

upper and lower large radiator hoses. Cost is $155.00 for both. The

Pegasus part # is:

The catalog describes them as "Bright Blue silicon rubber construction

with 3-ply reinforcement...." Temperature rating is -50degrees C

to +200 degrees C.

________________

Date: Mon, 12 Mar 2001 09:51:26 -0800 Got mine from Summit Racing. It's a Goodridge/Samco silicone upper/lower rad

hose set:

Cost me $156. Mine's blue but I think it also came in

yellow and red. Last I've heard Goodridge/Samco is stopping production due

to the dwindling market for these things. BTW, my Summit part# is:

________________

Date: Thu, 11 Feb 1999 07:35:15 -0600 I'm about to order up the parts to replace all the pressurized coolant hoses

in the system. The only ones I'm not sure of are the two for the

turbocharger. I couldn't see these from the top and didn't have the time or

facilities to jack the car up (its still in storage). How hard are these

two to replace, and how much of the engine needs to be torn apart to get to

them?

I counted 13 hoses total. If I've missed any, let me know. I might have

the in & out mixed up, but that doesn't really matter.

____________________

Date: Wed, 17 May 2000 17:30:46 -0500 I don't know of anyone that offers a kit in the sense of getting a

discounted, bulk price, but you can easily see (and order) all of the hoses

off the mazdatrix website .

____________________

Date: Tue, 28 Mar 2000 22:40:04 -0500 While I have yet to ascertain the real reliability of them, the Coolfex hose

system is constructued from seamless corrugated copper tubing designed to

withstand high vibration, high pressure use.

The exterior is chrome plated

and it has aluminum end covers finished in aluminum or chrome, black or

gold. there is a lifetime wrranty, though i haven't read it. 2 foot hose

with chrome covers costs $170 and for 3 foot length, $205.

They also offer a

variety of heater hoses of the same construction and finishes. I'm

installing the radiator hose right now and will be installing any others that

I can soon. Their number is 203-265-3617.

Date: Thu, 13 Apr 2000 11:04:45 -0700 Basically this is the hose that runs from the water pump that supplies

coolant for the turbos. It is well known for splitting and desperately needs

to be changed. Especially on high mileage 93 cars such as mine. 94K and

going.

Mine cracked and made a big coolant explosion after I turned off the car in

January.

So for all you who haven't changed it yet. Now you know where it is. Go

change it before you pop.

You have to remove Air Pump to get to it.

(Ed.'s note: I linked to his web site so the picture shows up inline

here. Here is the original link:

http://members.xoom.com/diepat_rx7/rx7/boom/9.jpg

).

________________

Date: Sun, 9 May 1999 07:04:07 -0700 (PDT) I used purosil 10mm silicone hoses for the feed and return from the

turbos. also on the throttle and under the throttle body feeding to

the thermostat. I have this on since June 98 and it seems to be fine;

no hardening or cracking or swelling. The OEM I had on the turbos had

swollen up to three times its size and was ready to burst. I'll see

if the silicone line will hold up.

_________________

Date: Thu, 13 Jan 2000 17:43:55 -0500 Here is the info on the 3rd gen coolant hose kit:

Goodridge silicone radiator hose p/n GS53-Y

The Y in the part number is Yellow so substitute the Y with R for red...etc.

Summit Racing should be able to get them for you. I bought mine from a local

speedshop, B&B Performance (203)481-0366

__________________

Date: Wed, 05 Feb 2003 09:38:24 -0500 I replaced the turbo cooling hoses three years ago with Teflon Hose Assemblies

w/Stainless Steel Braided Covers, still holding strong! Here is my post from what

seems like centuries ago:

Due to the many requests pertaining to the Teflon Hose Assemblies with Stainless

Steel Braided Covers, the supplier and part numbers are as follows:

McMaster-Carr: (330)995-550 or http://www.mcmaster.com

Hose #52515k24 $4.53 per footClamp #54195k14 $4.40 per pack of 10 (marine grade)

Approximately one foot of hose is needed, but order 1.5 feet (little extra in case

you screw up the first hose like I did). Trace the new hose along your bloating hose

and cut the new hose about a half-inch shorter than OE hose. If one cuts the new

hose to the same length as the OE, you will NOT have enough space/room to manuver in

place. Trust me, this was the most difficult part of the job, real PITA. Before

installing the hose, place the hose clamps on the hose. This will save allot of

skin! Trying to maneuver the clamps in place in the when the hose is mounted is

extremely difficult. Just to be safe, install four clamps per hose. I found my

first time through (note I said first) that a clamp was over-tightened(oops). Once

the engine got up to temp the metal expanded (popping the clamp) thus spraying

coolant on the turbos. Being more careful the second time, all went well.

Here is a universal fit electric water pump:

http://www.daviescraig.com.au/

_________________

From: Steve Cirian Agreed in terms of entropy, but in the real world it might depend

more on how each was implemented. i.e.- maybe the alternator has less

friction and power loss than the mechanically-driven pump. (i.e.-

poorly designed mechanically-driven pump). Also, for the

mechanically-driven pump you are adding an additional pulley, and

more friction, plus a longer belt (i.e.- more rotating mass (kind

of)).

An electrical pump would be able to be driven at a constant speed

instead of varying with engine RPMs. Therefore it would require the

same energy regardless of engine speed, whereas the mechnical one would

rise in speed as RPMs rise and thus induce greater power loss to

overcome friction and to pump more water. (I know you would probably

want to pump more water at higher RPMs, but you may not need to do it

at a 1:1 ratio as forced by the mechanical drive. Does anyone know

if the electrical pumps can vary their RPMs, and is it tied to a

heat sensor of some sort?)

Also, if the electrical pump is mounted remotely, you would have

moved some heat away from the engine. This would help engine

efficiency.

The drag race engines probably use a magneto. (Or am I really dating myself here?) But I am

not sure if that powers anything except the ignition. The accessories could all be driven from a

battery. Almost any battery should have enough juice to power the water pump, fuel pump, etc.

for about 4 seconds :-)

_________________

water pump removal/replacement procedures.

________________

Date: Mon, 11 Oct 1999 22:13:00 -0400 See

http://robrobinette.com/water_pump.htm

for the water pump replacement how-to.

______________

Date: Fri, 8 Oct 1999 16:46:14 -0500 The seal between the engine and water pump is shot, as is the pump

mechanism. Only had about 25k miles on it - the pump was supposedly

replaced around 15k miles, about 40k miles now.

There is a kit that replaces the front water pump seal and the pump

mechanism, not the whole housing. Comes with the lower radiator hose,

pump, gasket, and coolant sensor. The Mazda parts person seemed upset that

I knew about such a thing without them having diagnosed a warranty repair.

Info below:

Date: Tue, 14 Jul 1998 10:18:00 -0500 You should be running a coolant mixture of 1 part antifreeze to 2 parts

distilled water plus a whole bottle of RED LINE WATER WETTER.

If your engine compartment is dirty then it should be completely GUNKed

when only warm and then washed down with soap and then rinsed. A clean engine

is a cooler engine.

If you have used tap water in the engine for extended periods of time;

then flush the cooling system first with aluminum safe cleaner, then

distilled water, then add the mixture.

My temps have been about 195 in steady traffic and up to 210 in stop and

go with the AC on during these hot days. The orig thermostat is still in.

______________

Date: Wed, 24 Mar 1999 23:04:28 -0600 I'd highly recommend Havoline's Extended Life antifreeze/coolant (orange

colored). This stuff is the way to go, and nothing compares to it. It is a

patent protected, silicate free formula. What this gets you is no silicate

"slime" in your cooling system, longer water pump seal life, the best

corrosion protection there is, and 5 year coolant life. GM puts it in

nearly all their new cars, and can justify the increased coolant price from

water pump warranty reduction alone.

If you do any racing or autocrossing, you probably want to run a mix to get

you to the freeze protection you require in your area. Extra antifreeze

reduces the heat capacity of the mixture. Otherwise, 50/50 mix should be

just fine, unless your cooing system is in very bad shape.

_______________

Date: Mon, 27 Mar 2000 18:56:52 -0500 He had an engine failure and found it attacked the O-rings, chewed them and

left alot of white crustation. I can't remember the mileage it took before he

tore the engine apart, but I recall he said it was within a period of 1 year

or so. The best source of coarse is Dave himself. Stop by their

site

and drop him a line.

He said it works great in

piston engines as the gaskets have shown to negative reaction to it and he

was able to see a few degrees drop in temp, but in rotary engines, the

O-rings are too fragile and sensative. Now please remember that this is

Dave's opinion and several factors could have resulted in the failure, ie it

is not a scientific experiment, but due to this he urged us to stay away

from Dexcool.

Before the subject comes up, I will go ahead and mention he

found no difference (atleast on the street) using Redline Water Wetter. His

comments were, it didn't help but didn't hurt anything either. His advice on

lowering engine temps is to bore out the cooling passages in the housings,

the idea is to keep it rough (ie don't go for a polished finish) to increase

the surface area the coolant is in contact with the housing. He found this

yields 8 to 10 degree difference. Of coarse there is also the obvious fact

that aftermarket radiators are the best cooling mod...

_________________

Date: Mon, 27 Mar 2000 21:21:42 EST Thanks for the heads-up Wael, but I'm still left wondering which type of

"orange coolant" was used in this engine.

I made sure to use the Havoline

Dex-Cool since it is a proven coolant and very safe on gaskets, etc...

BUT I

have heard of such problems with the Prestone long-life coolant, also orange.

Maybe I'll be my own "guinea pig" since my FD just turned 85k on the

original motor... and the orange coolant has already been in there two years

with no abnormalities noted.

_______________

Date: Tue, 28 Mar 2000 16:53:15 -0800 With the recent comments about the use of Dex-Cool antifreeze in the

rotary possibly causing damage, I decided to give Dave at KD Rotary a

call to get the "straight story". Dave was kind of the instigator of this

information during a tech seminar at KD Rotary just recently. Dave was

pleasant to talk to, and was willing to share the whole story with me. This

is a summary of what he had to say concerning the Dex-Cool.

The product in question was Havoline's Dex-Cool. It was not Prestone's

Extended Life antifreeze. Both are orange in color, and both are

phosphate and silicate free. Beyond that, who knows the "secret"

chemical composition of each. Its unknown what Prestone Extended will

do in a rotary. I've had it in my Toyota pickup (V6) for about a year, and

the guts of the radiator still look new (looking in the filler neck).

Dave said he has rebuilt hundreds, if not a thousand of rotary engines over

the years, and has come across three separate instances where the innards

of the engines where coated with a "white powdery coating". It seems to

cake up at places like seams on hose connections, etc. Also, the O-rings in

these engines where "chewed up". Hard to say if it was a chemical

degradation (doubt it), or erosion from the "white crude" being in the

coolant. In one instant, the motor was one he had rebuilt, then had to tear

down again about a year later, so he say the "before" and "after" results of

the use of Dex-Cool.

We tried to come up with theories why it only seems to occur when used

in a rotary engine. One comment was that every rotary engine on cold

startup will leak a small amount of combustion gas into the coolant system

to some degree. Its possible that the buildup of hydrocarbons in the

coolant may have some bearing. Also, especially in the [3], there is some

hot localized heat due to the turbo charger cooling loop. Plus, its unknown

if water-wetter was used, and if that had any bearing.

My theory is, if this is occurring in your rotary you should be able to open the

coolant system filler cap when the engine is stone cold, and see the white

crud inside the walls of the coolant passages.

Safety Note: Only open the filler cap when engine is completely cold. I don't

want anyone burned up on my account.

_________________

From: dave@KDR

Hey Mike...here are the three following reasons and opinions for what they

are worth...

The first time we had rebuilt an 87 Tll...the customer installed at home

with our help and we watched him fill it with dexcool (havoline) and

distilled water...six months later at the drags on a stock engine he spiked

at 18 lbs and blew it...so we tore down for him and the engine coolant ports

were completely corroded...and the coolant seals showed really excessive

corrosion...we were very suprised..he flushed the heater and rad...went back

to prestone..

The second was a Hayes rebuilt that came to us with 8 K on it..the 3mm were

done poorly and the engine failed..when we tore it down it was the

same...the Hayes coolant seals were pitted terrible and the white powder all

over the aluminum rotor housings...we asked the cust and he said he used

dexcool and distilled water...

The third was 93 that the customer changed to

dexcool at 55K miles...the engine had coolant seal failure at 71K...it was

the same as the other three as the coolant seals were destroyed...the engine

in this one was never beat..older gentleman who maintained it religously and

never over heated...all highway mileage...so now what...

While we believe

dexcool is a great product we believe they may be several reasons for this

issue that is not prevelant in piston engines...(I ran dexcool in my 626

with never an issue...191K)...

my opinions are this...

Hope this helps...holler if any issues or questions...thanks a

mill..dave@KDR

_________________

Date: Sun, 2 Apr 2000 23:42:41 -0500 I'm cc'ing the list on this to spread around what I know. I haven't been

following the list very closely for the last few months, but thanks for

prompting me on this issue. I won't get too in depth right now, but the

ONLY problem with Dex-cool is that it can cause some silicone seals to take

an accelerated compression set. The effect is further accelerated with high

heat (roughly, 280 degF is a point to begin worrying). This comes straight

from an applications engineer at Texaco (actually Equilon, the joint venture

of Texaco & Shell, I believe). This is the one and only negative side

effect of Dex-cool. FYI - there are 20 Million GM vehicles on the road with

factory fills of Dex-cool and silicone seals in the cooling system.

All ethylene glycol coolants cause silicone rubber to take a compression

set. All silicones are porous, and the coolant gets into the pours, somehow

reducing the rubber's resilience. Texaco's recent research suggests that

there is some sort of protection mechanism of silicone by silicates in

conventional coolants (Dex-cool is silicate free). However, one thing to

keep in mind is that most Japanese coolants are very low/no silicate

formulations, so the factory fill may have been a no silicate coolant to

start with.

Now the key questions we need to answer: are the inner coolant seals indeed

silicone rubber? Mazda USA tells me it is proprietary and won't say (side

note - I believe they did tell me that they are coated with Teflon, at least

on a 3rd gen. I called last summer and don't remember the conversation

precisely anymore). Of those that say, yes they are silicone, what evidence

do they have? Second - is the Mazda factory fill a low or no silicate

coolant?

I'll tell you that I worry way to much about my car, and loose too much

sleep over my worries. Even though my car shows no signs of leaking

o-rings, I still got a cooling system pressure tester for the weekend and

tested my car. As expected, it held pressure great for over 15 mins, no

leaks (although my cap is a bit weak - only holds about 10 psi). I've had

Dex-cool in my car for 11,000 miles (since July '98), with no Water Wetter

(which has a lot of silicates, defeating the purpose of Dex-cool. For those

that insist on using it, I'd try Diesel Water Wetter with has no silicates).

The one thing that worries me, is that I'd bet the inner o-rings live in

metal that routinely gets over 280 degF.

Even though I will be sacrificing some aluminum protection and heat

transfer, I'm switching back to conventional coolant - for now. My contact

at Equilon graciously offered to put some of the said seals in their

internal test if I'd send him one or two. Also, in about a month, we will

have a machine at work that can test polymers and tell you what they are

made of, including surface coatings. So, I need 2 - 3 new Mazda inner

coolant seals. I think they are around $18 ea. from a dealer. It would

sure be nice if someone out there would offer to take care of this and send

them to me. Since buying a tow vehicle to support my racing addiction, I

can barely afford a glass of water. The part number should be N326-10-B71A.

TIA!

________________

Date: Thu, 6 Apr 2000 17:26:59 -0700 As far as ethylene glycol (EG) interaction with silicon

o-rings, I would bet there is no concern here. Almost every

modern engine in the world today has some type of

rubber parts (o-rings, hoses, etc.), so I'm confident that

EG is safe for these materials.

Recommendation is to not use propylene glycol antifreezes.

There boiling point is lower than EG at the same temp

and pressure. They may be fine for a low performance car,

but not for the rotary. There is no known antifreeze that

I know of where you can run an unpressurized system.

If someone could invent that, they could get rich fast,

since keeping a cooling system under pressure requires

alot more design and materials effort than not.

IMHO, the best thing to do for a rotary is change the coolant

*every* year. The rotary engine has lots more combustion

blow-by (even with new o-rings) than a boinger, and this tends

to "poison" the coolant at a high rate. Plus, the way the

engine is designed, it is a virtual "electrolysis monster",

meaning there are alot of iron/aluminum contact areas in

the rotor housings/end and center housings. As the coolant

degrades with combustion poisoning, heat and age, these

areas tend to corrode first.

Editor's note: Mike Putnam and Derek Vanditmars have instruction

up on the San Diego club's web site on how to linearize the temp

gauge. The rest of the posts in this section probably do not need

to be read, since they are sort of the history leading up to this,

and Mike's page does a great job of explaining everything. --Steve

Date: Wed, 24 May 2000 08:01:36 PDT The instruction on how to linearize the third generation RX-7 temperature

gauge is available at:

http://www.geocities.com/sdrx7_club/technical.html.

_________________

From: "Drew" (drewm@earthlink.net) For those of you who don't know:

The FD cooling gauge is an idiot light with a needle. It doesn't move until

it is too late. The rotary o-ring seals are very heat sensitive, will shred

and require an engine rebuild. Accidental overheating is the #1 cause for FD

engine failure.

Matt Severson programmed an inline interpreter. This gauge will actually

move in relation to the engine temperature! On start up the needle will

sweep the entire range so you know the gauge is working.

There are two reading settings:

Implementation:

Problem:

We need the connectors from Sumitomo:

http://www.sws.co.jp/EWAB/PRD/FRM/FILE/02.htm

Does somebody have a resource for this? Sumitomo sells in blocks of several

thousand. But they do send out free samples in the 100-200 quantity range.

Matt has the p/n number, but he can't seem to get them to send the correct

samples.

__________________

From: Max Cooper (max@maxcooper.com)

Could one of these alternatives work?

___________________

Date: 16 Jan 00 16:51:08 EST Drew the part numbers are as follows:

The connectors are 14-way, so I need 14 terminals for each female and male

connector.